10

Removing the 4 Prong Drive Centre from the Headstock

The knockout bar is used to remove the drive centre from the headstock

spindle. To do so, insert the knockout bar into the hole positioned centrally in

the hand wheel, at the opposite side of the headstock from the drive centre

and give the drive centre a sharp knock to dislodge it. See

Fig.8.9

.

8. Assembly - cont.

Fig.8.9

Knockout bar

Indexing assembly

Fig.8.6

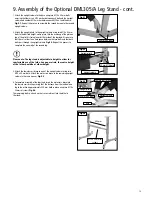

Installing the Indexing Assembly

Carefully screw the indexing assembly onto the headstock with an adjustable

wrench,

Fig.8.6

.

Fitting the 4 Prong Drive Centre to the Headstock

Before fitting the drive centre, the faceplate must be removed from the

lathe. Place the knockout bar in the circular hole in the spindle nose and

hold firmly to ensure the spindle does not turn. Now use the spindle

wrench on the faceplate collar to loosen the faceplate, turning anti-

clockwise, see

Fig 8.7

.

Insert the drive centre into the headstock spindle,

Fig.8.8

.

Warning: Always disengage the indexing lock before turning

the machine on.

i

Kg

Drive centre

Fig.8.8

Spindle

Knockout bar

Spindle wrench

Fig.8.7

Spindle

Faceplate

Fig.8.4

Tool rest holder

The nylon locking nut can now be tightened until the tool rest holder is held

firmly on the lathe bed but can slide freely along its length,

Fig 8.4

.

Installing the Tool Rest to the Tool Rest Holder

Loosen the locking handle and insert the tool rest into tool rest holder, adjust

the height as required and tighten the locking handle,

Fig.8.5

.

Clamp

Fig.8.5

Tool rest

Tool rest holder

Locking lever

Locking handle

Summary of Contents for DML305

Page 24: ...24 16 Parts Diagram List ...

Page 27: ...27 ...