CONNECTIONS

– ELECTRICAL

25

Warning: THE WATER HEATER MUST NOT OPERATE WITHOUT THE CIRCULATING PUMP RUNNING.

ELECTRONIC THERMOSTAT TEMPERATURE SETTING (SET POINT)

For reasons of safety and economy, we recommend that the electronic thermostat set point is set at the lowest

temperature that will provide sufficient hot water. Discuss the temperature setting requirements with the

householder or responsible officer. Refer to

“Temperature Control”

on page

43

.

INTERMITTENT PUMP OPERATION

For applications utilising intermittent pump operation, a run on timer is provided (modulating models only). For

on/off models, an optional pump run on timer kit part number 56076874 must be fitted to the water heater to

prevent nuisance tripping of the high limit thermostat due to residual heat build up in the heat exchanger. The timer

should be set to allow the pump to operate (run on) for at least ten (10) minutes.

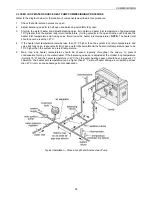

EXTERNAL CONTROLS

Modulating models can be wired for use

with an external control such as a remote

thermostat or a remote time switch. To

connect an external control to the water

heater it is necessary to remove the

bridging wire between terminals marked

“TO

TANKSTAT

”

and

“FROM

TANKSTAT

” and connect the external

control across these two terminals (refer

to the diagram opposite and to the wiring

diagrams on pages

28

to

33

.

On/Off models may be wired as depicted above with the installation of kit 56076874 (supplied separately).

Where a remote thermostat such as a tankstat is utilised, the water heaters electronic thermostat set point should

be adjusted to 5º higher than the setting on the remote thermostat (Refer to

"Temperature Control"

on page

43

.

POWER FLUEING

If the flue cannot be designed as outlined in the

„Indoor Installation‟

section on page

12

, then a power flue may be

required. Power flues must be designed by persons competent to do so and must be electrically interlocked with

the water heater(s). Contact Raypak for power flue wiring diagrams.

FLOW SWITCH

A flow switch is provided with the water heater and is wired to prevent operation of the main burner in the event of

no water flow. Refer to

“Flow Switch Adjustment” on page

42

.

Warning: THE WATER HEATER MUST NOT OPERATE WITHOUT THE CIRCULATING PUMP RUNNING.

BUILDING MANAGEMENT SYSTEM (BMS)

For applications requiring connection to a building management system, relays are installed as standard on all

models

to provide „run‟ and „fail‟ status indication. The diagram on page

26

details a typical BMS system interface.

AMBIENT AIR COMPENSATOR

An Ambient Air Compensator (not supplied) may be installed and connected to the RWF55 electronic thermostat

on modulating models (refer to

“Ambient Air Compensator”

on page

49

).

CONTROL PANEL ACCESS

To access the electrical enclosure:

Remove the 3 Hex head screws from the clear Perspex front panel.

Remove the front panel.

Summary of Contents for B0507

Page 26: ...CONNECTIONS ELECTRICAL 26 Wiring Diagram for Typical BMS System Interface ...

Page 28: ...CONNECTIONS ELECTRICAL 28 WIRING DIAGRAMS ON OFF MODELS 1000MJ NG ...

Page 29: ...CONNECTIONS ELECTRICAL 29 ON OFF MODELS 1000MJ LPG ...

Page 30: ...CONNECTIONS ELECTRICAL 30 ON OFF MODELS 1000MJ ...

Page 31: ...CONNECTIONS ELECTRICAL 31 MODULATING MODELS 1000MJ NG DRAWING No 96159611B ...

Page 32: ...CONNECTIONS ELECTRICAL 32 MODULATING MODELS 1000MJ LPG DRAWING No 96159610C ...

Page 33: ...CONNECTIONS ELECTRICAL 33 MODULATING MODELS 1000MJ DRAWING No 96159613B ...