Wuhan Raycus Fiber Laser Technologies Co., Ltd.

User Guide of RFL-C15000TZ

53

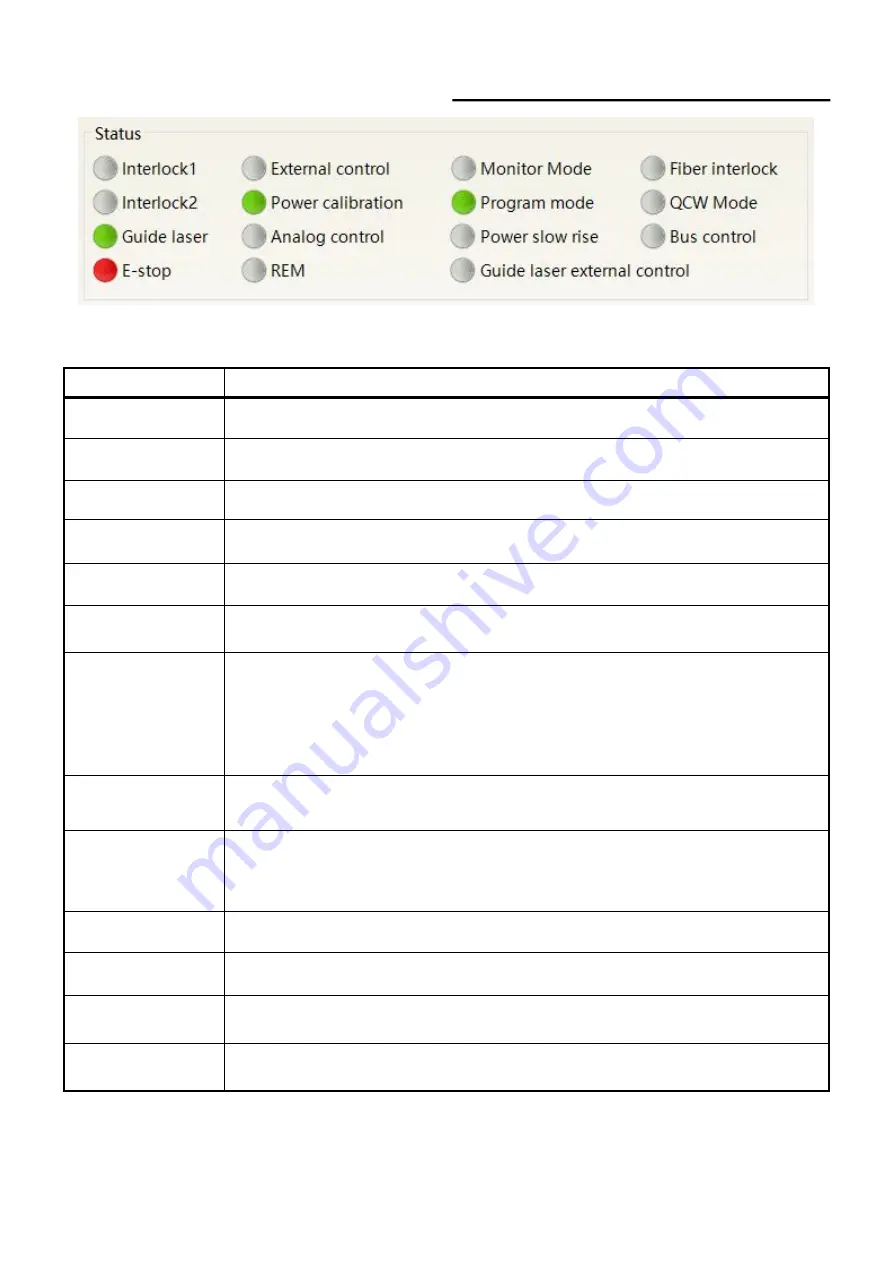

Figure 34 A diagram of the laser's working status display area

Table 14 The laser main display area clarification

Display

Content explanation

Emergency stop

Red: emergency stop button on front panel is pressed

Gray: emergency stop button is reset

REM

Green: laser works in REM mode

Gray: laser works in ON mode

Red laser external

control

Green: laser works in red laser external control mode

Gray: laser works in red laser internal mode. Laser on/off controllable by software

Red laser

Green: red laser is on

Gray: red laser is off

Output fiber Interlock

status

Green: Interlock spot at output fiber end is make

Gray: Interlock spot at output fiber end is break

External control

model

Green: Laser works in external control mode

Gray: laser works in internal control mode. Laser on/off is controllable by software

Power correction

Green: Laser operates in power linear correction mode, in which control system

automatically adjusts the laser's output power. It makes the output power linear, with a

longer response time for AD analog in this mode, longer than 1mS.

Gray

:

laser operates in non-correction mode, and the external 0-10V analog voltage is linear

only with the current of the pump auxiliary tube. The response time for this mode AD

simulation is less than 100uS

AD model

Green: Laser power is determined by the 0-10V analog voltage on XP4 when laser works in

AD mode.

Gray: laser power is set by PC software or communication commands.

Monitoring model

Green: PC software is in monitoring mode. User can monitor laser status only, but not able

to take control of laser. Monitoring model is activated when interface 10001 of laser

occupied.

Gray: PC software operate in normal mode

InterLock1 make

Green: XP2 leg 17,18 on safety interface make

Gray: XP2 leg 17,18 on safety interface break

InterLock2 make

Green: XP2 leg 19,20 on safety interface make

Gray: XP2 leg 19,20 on safety interface break

Programming model

Green: Laser is in program mode

Gray: Laser is not in program mode

Power slow rise &

fallmode

Green: laser works in power slow rise & fall mode

Gray: laser does not work in power slow rise & fall mode