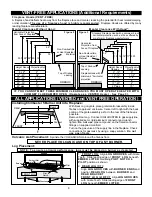

ALL APPLICATIONS (VENTED and VENT FREE OPERATION)

Ultrasonic Remote Control (Manual or Remote ON-OFF)

Before you start: Both the transmitter and receiver require 9 volt

batteries to operate in remote control.

The blue and black receiver wire leads are for the optional sound producing

device (CRACKLER Model CF5).

The receiver must be protected from overheating. Locate receiver well

away from heat. Accessory REMOTE LOG HOUSE (Model "RH") is

available for use as a heat resistant "log" in which the receiver portion of a

Wireless remote option may be located.

Operation Tips: This is a sound operated remote (unlike TV remotes which

SWITCH OFF REMOTE

ON ACCESS

ON

When switching

from REMOTE to

OFF, first turn set

off using the

transmitter.

Remote: Switch to

REMOTE ACCESS

ON. Aim, press button

and hold transmitter at

receiver.

Manual: Switch from

OFF to SWITCH ON;

SWITCH ON to OFF

are Infrared and operate instantly) and requires you to aim and hold the transmitter for 1 to 3 seconds to

operate. Manual Operation: (Receiver switch position ON or OFF) does not require batteries.

Remote Operation: Requires good batteries. If you turn the gas log on using the remote control and then turn

the set off by sliding the receiver switch from REMOTE to OFF, when you replace the switch to REMOTE it will

remain in the last selected remote position (in this case ON) and turn the gas log on.

To shutdown overnight or for any prolonged period, slide receiver switch to "OFF".

C7-R or DFC7-R (Remote Control) LIGHTING and OPERATION

Pilot Lighting (Remote Operated Valve):

N O T E : The Operating Dial has complete control of gas to

pilot and burner. The Operating Dial cannot be turned to

"OFF" without first depressing dial in "PILOT" position and

then rotating clockwise to "OFF". (see Figure 9)

1.

Depress and turn Operating Dial to "OFF" position. (Fig 9)

2.

Wait at least 5 minutes to allow gas which may have

accumulated around burner to escape.

3.

Turn Operating Dial to "PILOT" position.

Pilot Set Screw under plate here.

Operating Dial

Gas Dial

Figure 9

.

.

.

4.

Depress and hold until air is bled and gas flows to pilot.

5.

Light pilot. Continue to depress and hold in Operating Dial. Ignite pilot by cycling Operating Dial from

PILOT to IGN. Once pilot lights, continue to hold in Operating Dial until the Pilot flame remains lit when

knob is released (approximately 60 to 90 seconds). If Pilot does not remain lit, repeat steps 1 through 5 and

allow more time after Pilot Lighting before releasing knob. (Figure 9)

6.

Turn Operating Dial to "ON".

Ignition Interlock. The Ignition Interlock device prevents the re-establishment of gas flow following a loss of

pilot flame (Approximately five minutes). Releasing the Operating Dial prior to establishing a pilot may

engage the Ignition Interlock requiring approximately 5 minutes before you can attempt to re-light the pilot.

Burner ON or OFF and Adjustment (Remote Operated Valve): With the Operating Dial (Figure 9) in

the "ON" position, depress the "UP" or "DOWN" button on the transmitter to turn on/off and adjust flame height.

Complete Shutdown (Including Pilot): Depress "DOWN" button on transmitter until flame is completely out.

Slightly push and turn Operating Dial to "OFF". (Figure 6)

Pilot Location:

Pilot is located on right side behind front burner.

OP AMERICA Standard (Remote Models)

The Pilot flame should be steady and soft blue surrounding 1/8

inch of the thermocouple tip as shown in Figure 10.

OP AMERICA Millivolt (Switch Model)

NOTE: The OP America Millivolt Pilot/ODS is equipped with a quick

acting thermocouple allowing gas flow to the pilot after

approximately 30-40 seconds. An additional 60 to 90 seconds time

is required to fully heat the thermogenerator and allow gas to the

main burner(s).

Pilot Flame Adjustment. Pilot flame should be steady and soft

THERMOGENERATOR (Switch Models)

LP THEMOCOUPLE

NAT GAS

THERMOCOUPLE

PIEZO SPARKER

PILOT FLAME

Figure 10

AIR INTAKE

HOLES

blue extending approx. 1 inch beyond the pilot tube. If adjustment is necessary, use a narrow long stem screw driver

to turn pilot adjustment screw (see Figure 8-Switch or Figure 9-Remote). To adjust turn clockwise for less pilot flame,

counterclockwise for more pilot flame. There is no pilot adjustment available on C7 or DFC7 Manual Models.

IMPORTANT SERVICE TIP! Obstructed Pilot Air Intake Ports result in an improper gas/air mixture

and a weak pilot flame. Weak pilot flame is the NUMBER 1 SERVICE ISSUE RE NUISANCE

SHUT-OFF. Using canned compressed air , pipe cleaner or an artist's brush, clean out the opposing

Air Intake Ports located at base of Pilot (where gas supply line attaches to pilot). (Figure 10)

.

9