9

INSTALLATION \ WIRING

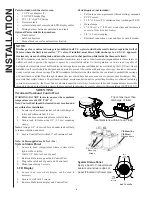

PLUMBING

WARNING:

• All installations made below the waterline MUST be

protected by installing vented loops in proper location

• Always double-clamp fittings below waterline

• Do Not use metal fittings

NOTE: Use teflon tape or non-permanent thread sealing

compound on threaded PVC fittings and connections. Avoid

low areas in hose that would allow untreated waste to collect.

1. Connect discharge of toilet to one inlet port.

2. Insert plug or second toilet discharge into other inlet port.

3. Determine position and glue discharge elbow to top of

tank using PVC cement.

4. Connect discharge hose from elbow to thru hull fitting.

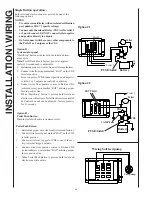

WIRING

WARNING: Hazard of Shock and Fire

•

Always use proper wire, wire connectors and fuse/

circuit breaker. See Specification Chart.

•

Secure wire properly.

•

Do not connect other appliances to electro scan circuit.

•

Make sure power is off before proceeding.

•

Improper wiring can damage the Circuit Board and

void warranty.

Treatment Unit

1. Determine proper wire size from wire chart on

specifications page.

2. Run supply wire from source Positive (POS) to control

unit and Negative (NEG) terminals on Treatment tank.

3. Fuse or circuit breaker must be installed between source

and electro scan on positive wire.

NOTE: Future access to control box is imperative. If unit is

installed in an area where access will be difficult contact

Raritan for instructions on mounting the control box for

distance more than two feet.

System Status Panel

1. Connect cable from System Status Panel to panel 1 jack on

Control Unit.

2. Secure cable strain relief.

3. Follow same procedure for panel 2 if dual installation.

LCD Display

1. Connect cable from LCD Display to display jack on the

Control Unit.

2. Secure cable strain relief.

Discharge from toilet:

each side if dual installation

one side in single installation

Discharge from electro

scan to thru-hull

Orange

+

-

BATTERY

Black

White

Red

electro scan

Orange

Black

White

Red

Main Fuse/

Circuit Breaker

Control Unit

LCD Display

System Status

Panel

Summary of Contents for Electro Scan EST12

Page 12: ...12 This page left blank...