7

SPECIFICATIONS

U.S.C.G. Type I MSD Certification #159.015/0107/1

Maximum Roll/Pitch Angle: 30° Capacity: 575 Gallons Per Day

Maximum Temperature Exposure: 120° F (49° C)

Maximum Total Flush Volume: 1.5 gallons/flush (5.7 liters/flush)

Maximum cable length for LCD Dispaly: 16' (5M)

Maximum cable length system status panel: 25' (7.6M)

s

t

i

n

U

e

g

a

t

l

o

V

t

i

u

c

r

i

C

e

s

u

f

/

r

e

k

a

e

r

B

)

s

p

m

a

(

e

z

i

s

w

a

r

d

.

p

m

A

l

a

n

i

m

o

n

@

e

g

a

t

l

o

v

0

1

t

e

e

f

5

1

t

e

e

f

0

2

t

e

e

f

5

2

t

e

e

f

0

3

t

e

e

f

0

4

t

e

e

f

0

5

t

e

e

f

C

D

V

2

1

0

6

7

3

G

W

A

6

G

W

A

6

G

W

A

4

G

W

A

4

G

W

A

2

G

W

A

2

G

W

A

1

C

D

V

4

2

0

5

7

2

G

W

A

0

1

G

W

A

8

G

W

A

6

G

W

A

6

G

W

A

6

G

W

A

4

G

W

A

4

C

D

V

2

3

0

5

5

2

G

W

A

2

1

G

W

A

0

1

G

W

A

0

1

G

W

A

8

G

W

A

8

G

W

A

6

G

W

A

6

.

1

.

e

c

r

u

o

s

o

t

k

c

a

b

d

n

a

ti

n

u

o

t

e

c

r

u

o

s

m

o

r

f

e

r

a

s

e

c

n

a

t

s

i

D

.

2

m

m

(

G

W

A

m

u

m

i

n

i

m

e

ri

w

r

o

t

c

u

d

n

o

c

d

e

d

n

e

m

m

o

c

e

R

2

.

p

o

r

d

e

g

a

tl

o

v

%

3

r

o

f

)

.

3

5

0

1

n

o

d

e

s

a

b

e

r

a

s

e

z

i

s

r

o

t

c

u

d

n

o

c

d

e

d

n

e

m

m

o

c

e

R

o

.

n

o

it

a

l

u

s

n

i

d

e

t

a

r

C

.

s

g

n

it

a

r

n

o

it

a

l

u

s

n

i

r

e

h

t

o

r

o

f

s

d

r

a

d

n

a

t

S

C

Y

B

A

o

t

r

e

f

e

R

.

4

,

s

e

ir

e

tt

a

b

n

o

k

r

o

w

o

t

d

e

n

g

i

s

e

d

s

i

ti

n

U

e

s

u

t

o

n

o

d

y

l

p

p

u

s

r

e

w

o

p

d

e

r

e

tl

if

n

u

C

D

V

2

1

e

s

u

F

/

t

n

i

o

p

p

ir

T

e

g

a

r

e

p

m

a

m

u

m

i

x

a

M

C

D

V

4

2

e

s

u

F

/

t

n

i

o

p

p

ir

T

e

g

a

r

e

p

m

a

m

u

m

i

x

a

M

C

D

V

2

3

e

s

u

F

/t

n

i

o

p

p

ir

T

e

g

a

r

e

p

m

a

m

u

m

i

x

a

M

r

o

t

o

M

r

e

x

i

M

s

p

m

a

5

3

/

s

p

m

a

9

w

a

r

d

p

m

a

5

s

p

m

a

5

3

/

s

p

m

a

9

w

a

r

d

p

m

a

4

s

p

m

a

5

3

/

s

p

m

a

9

w

a

r

d

p

m

a

4

k

c

a

P

e

d

o

r

t

c

e

l

E

s

p

m

a

5

3

/

s

p

m

a

5

3

w

a

r

d

p

m

a

5

2

s

p

m

a

5

3

/

s

p

m

a

5

3

w

a

r

d

p

m

a

2

2

s

p

m

a

5

3

/

s

p

m

a

5

3

w

a

r

d

p

m

a

2

2

r

o

t

o

M

r

o

t

a

r

e

c

a

M

s

p

m

a

5

3

/

s

p

m

a

0

3

w

a

r

d

p

m

a

0

2

s

p

m

a

5

3

/

s

p

m

a

0

3

w

a

r

d

p

m

a

6

1

s

p

m

a

5

3

/

s

p

m

a

0

3

w

a

r

d

p

m

a

9

CONVERSIONS

Wire - AWG to mm

2

Feet to Meters

t

e

e

F

0

1

5

1

0

2

5

2

0

3

0

4

0

5

r

e

t

e

M

1

.

3

6

.

4

1

.

6

6

.

7

2

.

9

2

.

2

1

2

.

5

1

G

W

A

6

1

4

1

2

1

0

1

8

6

4

2

m

m

2

5

.

1

5

.

2

0

.

4

0

.

6

0

.

0

1

0

.

6

1

0

.

5

2

0

.

5

3

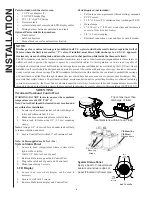

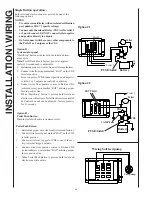

NOTES FOR WIRING:

Recommended Wire and Fuse/Circuit Breaker Size

Electronic trip Overload settings

IMPORTANT:

A salt feed tank is required when operating system with fresh or brackish water. Operating in low salt conditions

without the addition of salt will shorten life expectancy of the electrode plate and will void warranty.

The following are available to purchase:

NOT FOR USE WITH PRESSURIZED FRESH

WATER TOILETS:

Two Gallon (7.6 liters) Salt Feed Tank

(Part #31-3001) - Tank must be filled with a saturated salt

solution which is dispensed via a T-check valve into incoming

water. One system per toilet. For use in slightly brackish water.

If used in fresh water tank will only last for approximately 15

flushes of the toilet.

Four Gallon (15.2 liters) Salt Feed Tank

(Part #31-3002) - Tank must be connected to pressurized fresh

water and filled with solar salt. The saturated salt solution is

dispensed via a T-check into incoming water. One system per

toilet. Requires manual adjustment as water salinity changes.

Four Gallon (15.2 liters) Salt Feed Tank with Pump

(Part #32-3003 12 Volt and #33-3003 24 Volt) The tank

must be connected to pressurized fresh water and filled

with solar salt. The pump is controlled by the control

box. This system can only be used with the electro scan.

One system per electro scan. This is the most accurate

system to use as the amount of saturated salt solution is

controlled by the actual operating conditions of the

electro scan.

Salt Feed System Options

OK FOR USE WITH PRESSURIZED FRESH-

WATER TOILETS:

Summary of Contents for Electro Scan EST12

Page 12: ...12 This page left blank...