2

OPERATION

(depends on installation chosen)

Single Button operation -

Both toilet and electro scan are operated by one of the

following options:

Option #1: System status panel Touch Pad

"Start/Stop" button activates both the toilet and

treatment cycle. Button may be pressed as often as

necessary to flush toilet until system status green

light begins to blink 35 seconds after activation.

Note:

Toilet flush time is factory pre-set for 10

seconds and is adjustable, see "setting toilet flush

time"

Option #2: Toilet Push Button

-

Flushing toilet will activate treatment cycle. Flush

toilet as often as necessary until system status

green light begins to blink.

Independent Button operation -

"Start/Stop" button must be pressed before toilet is

flushed. Flush toilet as often as necessary until

system status green light begins to blink 35 seconds

after activation.

To Stop Treatment Cycle -

Pressing "Start/Stop" again stops the treatment cycle,

If wired per option #1 it will also stop the toilet from

flushing.

Notes:

1) Total flush volume must not exceed 1.5 gallons

(5.7 liters) per cycle.

2) Operating with red light for extended periods

will damage electrode and void warranty

How it works -

Each time the toilet is flushed an equal amount of previ-

ously treated waste is discharged. The electro scan does

not pump waste out. The flushing action of the toilet

moves the waste through the electro scan.

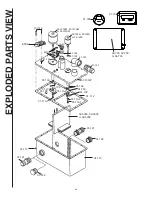

The first chamber macerates to reduce particle size. The

second chamber mixes to ensure uniform treatment of

contents. When the tank is full with salt water the electrode

plates, when electricity is applied, generate bactericide in

both chambers.

When first activated both motors come on and run for the

entire cycle. The user then has 35 seconds to flush toilet.

After 35 seconds the electrode is energized to begin the

treatment process which lasts for approximately 2 minutes.

Note: If the green light is not flashing during treatment,

the cycle has been automatically extended to ensure

proper treatment. The unit MUST not be operated in

extended cycle for long periods as damage to electrodes

will occur. Immediately attempt to determine the cause

and fix a red light condition.

Overboard

Electrode pack

From toilet

cross-over

Mixer

Macerator

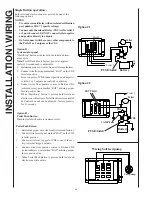

Solid Green-

OK to flush toilet

Blinking Green-

Normal operation, do not flush toilet

Blinking red-

Check warning on dispaly

Solid red-

Check error on display, Push and hold

mode button to clear

MODE DOWN UP

electro scan

LCD Display

System Status Panel

READY TO FLUSH

Summary of Contents for Electro Scan EST12

Page 12: ...12 This page left blank...