EPS 02 Operating Instructions

RACO Electronic Position Sensor

- Electronic Limit

Switches

- Very Accurate

- Easy to use

- Robust

- Dependable

- High Resolution

- Non Contact

Measurement

- Wide Temp.

Range

Introduction

The RACO electronic positioning system

EPS 02 has been especially designed for end

of stroke limit switch detection in electro-

mechanical linear actuators. The operating

principal is based on a non contact coupling

through a magnetic field. It detects angular

movement of the rotating motor shaft or

actuator screw in relationship to the

stationary sensor on the printed circuit board

and converts this signal into an absolute

linear position signal.

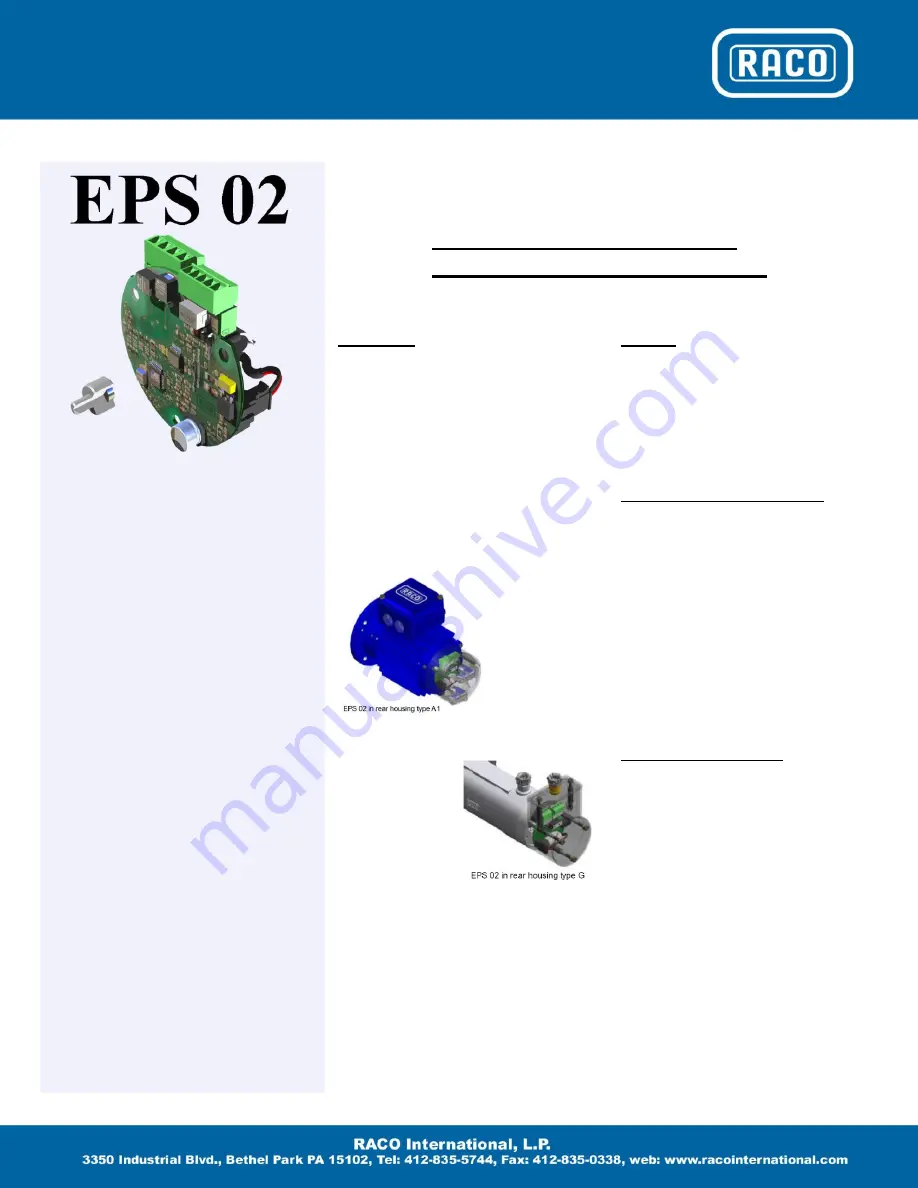

The electronic

position sensor

EPS

02

is

typically

integrated into

the

actuators

accessory

housing

“A”

mounted at the

opposite side of

the motor drive shaft.

If the actuator is

equipped

with

additional

auxiliary

equipment

like

hand wheel, etc..

the

electronic

position

sensor

will be mounted in

the lateral accessory housing “D” located at

the coupling housing connecting the actuator

screw with the drive motor.

In the EPS 02 the two end of stroke limits

can be set via on board push buttons and / or

the TTL level communication interface. In

addition an optional external reference limit

switch can be used. Three on board LED’s

will guide the user through the initial setup

procedure and will function thereafter as

operation control signals.

Function

The EPS 02 consists of two potential

free relay contacts, an input channel for

the motor over-temperature switch, and

the optional external reference limit

switch.

Motor Over-Temperature Switch

To protect the RACO actuator motor

from overheating, for example from

frequent starts and stops or excessive

overloading of the actuator, the opening

of the motor thermal switch will be

monitored. If the motor thermal switch

is wired into terminals X1 pin 4 and pin

5, both limit switch relay contacts will

open up in the event of an over

temperature. The red LED will blink on

and off to indicate that condition.

External Reference Switch

An optional external reference switch

can be used to indicate the retracted

position. The external device has to be a

normally open limit switch or a PNP

proximity switch. The switch will be

connected between terminal X1 pin 3

and pin 4. In the mode external

reference switch, the actuator will

retract until the external switch is made.

With the rising voltage edge at the input

X1 Pin 3 the internal EPS 02 position

reference point will be set to zero each

time. The extended stroke limit position

is defined by the stored stroke length

and the above described zero position.

Make sure that the external reference

switch is positioned in front of the

1

-30

-201

8