®

R&M Materials Handling, Inc

STAGEMAKER

®

COMPACT Concert Hoist

Springfield, Ohio USA

SM10 Installation & Maintenance Manual

: 800 955-9967

web:

www.rmhoist.com

June 2006

5 June 2006 35 SM10-M & I MANUAL - 2006 - 0.doc.

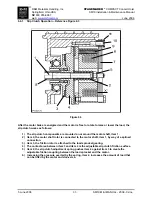

6.6.2

Slip Clutch Adjustment after Installation

1. Hook a load of at least 110 percent but not more than 125 percent of nameplate capacity.

2. Remove plastic cap from inspection hole in brake cover casting.

3. Raise load at slow speed and fast speed to test slip clutch operation.

4. Insert a socket (13 mm) through inspection hole, and slide it over nut (item 5 - Figure 6.3).

Turn nut in required direction:

•

INCREASE CAPACITY - Turn nut clockwise to increase the torque.

•

DECREASE CAPACITY - Turn nut counterclockwise to decrease the torque. Turn the

nut clockwise ½ turn before locking in place.

5. Repeat steps 3 and 4 until load can be barely lifted in fast speed.

CAUTION: DO NOT OVERHEAT. If overheated, clutch may not adjust due to instability of

friction surfaces.

6. Once adjustment is completed, install plastic cap.

7. Check function of clutch at 100 percent of nameplate capacity while in fast speed.

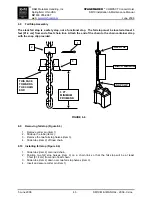

NOTICE

The slip clutch / Torque Limiter is a safety device to prevent overloading of the hoist. This device

is not intended for use as means to measure the weight of load being lifted.