®

R&M Materials Handling, Inc

STAGEMAKER

®

COMPACT Concert Hoist

Springfield, Ohio USA

SM10 Installation & Maintenance Manual

: 800 955-9967

web:

www.rmhoist.com

June 2006

5 June 2006 28 SM10-M & I MANUAL - 2006 - 0.doc.

4.3

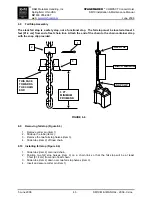

Operational Checks – No Load

•

Check hoist motor brake function. Run hoist (if inverted) or empty load block up or down to

check that load block does not drift more than 1.0 inch [25mm]. If so, adjust brake as

described in Section 6.

•

Run hoist (if inverted position) or empty load block (if normal position) down to check that fall

stop (located on free end of load chain) makes proper contact with limit switch and that limit

switch or slip clutch functions properly. Note – limit switches not provided for inverted

position use.

•

Run hoist (if inverted) or empty load block (if normal position) up to check that load block

makes proper contact with limit switch and that limit switch or slip clutch functions properly.

Note – limit switches not provided for inverted position use.

•

Run empty load block up and down several times while checking for proper tracking of load

chain.

4.4

Operational Checks – With Load

•

After completion of no-load operational tests, the user / owner should perform a full load test

even though each complete hoist is load tested at factory.

•

Lift a near capacity load about one (1) foot [30cm] above floor level. Check that brake holds

load. Also, check stopping capability of brake when lifting to a stop and lowering to a stop.

•

Move trolley the full length of monorail or crane beam. Check for any binding of trolley wheels

on flange and/or interference at splice joints, hanger connections / bolts, etc.

•

Check contact with stops. Contact with stops

SHALL

only be made with trolley bumpers.

Stops that are designed to make contact with wheels

SHALL NOT

be used.