QUANTECH

FORM QTC2-eg1 (515)

66

2.03 REFRIGERANT CIRCUIT COMPONENTS

Each refrigerant circuit shall include liquid line shutoff valve with charging port, low side

pressure relief device, filter-drier, solenoid valve, sight glass with moisture indicator, ex-

pansion valves, and flexible, closed-cell foam insulated suction line. Unit also includes

service isolation valves as standard.

2.04 HEAT EXCHANGERS

A. Evaporator:

1. Evaporator shall be brazed-plate stainless steel construction, single or dual circuit

heat exchangers capable of refrigerant working pressure of 650 psig (3103 kPa)

and liquid side pressure of 150 psig (1034 kPa)

2.

Evaporator shall be covered in 3/4" (19mm) flexible, closed cell insulation, thermal

conductivity of 0.26k (BTU/hr-fT2-°f]/in.) maximum.

3. Cooler shall have thermostatically controlled heaters to protect to -20°f (29°C) am-

bient in off-cycle.

4. Brazed plate heat exchangers shall be Ul listed.

5. installing contractor must include accommodations in the chilled water piping to

allow proper drainage and venting of the heat exchanger. A strainer with a mesh

size between 0.5 and 1.5mm (40 mesh) is recommended upstream of the heat ex-

changer to prevent clogging.

B. Air Cooled Condenser:

1. Coils: internally enhanced, seamless copper tubes, mechanically expanded into

aluminum alloy fins with full height collars. Subcooling coil an integral part of con

-

denser. design working pressure shall be 650 PSiG (45 barg).

2. low Noise fans: Shall be dynamically and statically balanced, direct drive, propel-

ler type fan, providing vertical air discharge and low sound. Each fan in its own

compartment to prevent crossflow during fan cycling. Guards of heavy gauge, PVC

(polyvinyl chloride) coated or galvanized steel.

[

OPTIONAL

]: Ultra-Quiet fans

3.

Fan Motors: High efficiency, direct drive, 6 pole, 3 phase, insulation class “F”, cur

-

rent protected, Totally Enclosed Air-over (TEAo), rigid mounted, with double sealed,

permanently lubricated, ball bearings.

2.05 CONTROLS

A. General: Automatic start, stop, operating, and protection sequences across the range

of scheduled conditions and transients.

B. microprocessor Enclosure: rain and dust tight NEmA 3r/12 powder painted steel cab-

inet with a gasket sealed protective cover.

Guide Specifications (Cont'd)

Summary of Contents for QTC2015T

Page 4: ...QUANTECH FORM QTC2 eg1 515 4 This Page Intentionally Left Blank...

Page 12: ...QUANTECH FORM QTC2 eg1 515 12 This Page Intentionally Left Blank...

Page 25: ...FORM QTC2 eg1 515 QUANTECH 25 Unit Dimensions English Cont d QTC2025T LD18674...

Page 33: ...FORM QTC2 eg1 515 QUANTECH 33 45 1 8 18 1 2 LD18682 Unit Dimensions English Cont d QTC2045T...

Page 47: ...FORM QTC2 eg1 515 QUANTECH 47 Unit Dimensions Metric Cont d QTC2045T 424 LD18702...

Page 57: ...FORM QTC2 eg1 515 QUANTECH 57 Power Wiring LD18707...

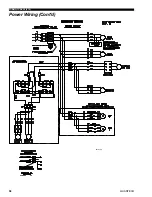

Page 58: ...QUANTECH FORM QTC2 eg1 515 58 LD18744 Power Wiring Cont d...

Page 59: ...FORM QTC2 eg1 515 QUANTECH 59 Power Wiring Cont d LD18746...

Page 60: ...QUANTECH FORM QTC2 eg1 515 60 Factory wired with optional transformer LD03611 Control Wiring...