Page 27

April 19, 2010

4100-I ACT Wood Insert

250-7201F

R

2

6-1/8"

2-1/4"

1

1

2

2

4

4

4

4

4

4

4

4

4

4

6

6

4

4

5

5

5

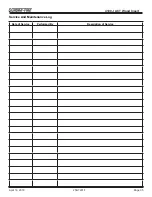

Brick Replacement Instructions

The firebox is lined with high quality firebrick which has

exceptional insulating properties. There is no need for a

grate, simply build a fire on the firebox floor of your insert.

1

. Be certain coals are completely cold. Remove all old

brick and ash from unit and vacuum out firebox.

2. Remove new brick set from box and lay out to THE

diagram as shown.

. Lay bottom bricks in unit.

4. Install rear bricks on the top of the bottom bricks. Slide

top of bricks under clip on back of firebox wall and push

bottom of brick back.

5. Install side bricks. Slide top of brick under clips on side

of firebox and push the bottom of the brick until it is flush

with the side of the unit.

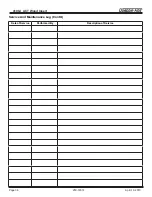

Baffle Removal & Installation

1. Remove all ash from firebox, and extinguish all hot embers

before disposal into a metal container.

2. Remove ceramic blanket from above the baffle.

. With a /16” Allen wrench, remove 2 front manifold tube

retainer bolts on the air channel under the end of the front

tubes. NOTE: Soak the bolts with penetrating oil for at least

15 minutes before trying to remove them.

Figure 27.1.

4. To remove manifold tubes, slide the tube to one side until

one end is out of its hole. Then, while lifting that end of the

fiber board baffle, pull tube up over the air channel and out of

hole at the other end. It is necessary to remove the first two

tubes in order to remove the baffle.

NOTE

: When replacing

the manifold tubes, be sure the tube with the larger holes is

placed in the front for your insert to operate properly.

5. Slide fiber board baffle forward to front of stove and straight

out through door.

Figure 27.2.

6. To install the fiber board baffle, repeat steps 2 through 4 in

reverse. Be sure the fiber board baffle and ceramic blanket

are pushed back fully into position and the ceramic blanket

lays flat.

Ceramic Blanket

Baffle

Figure 27.2 - Baffle & Ceramic Blanket on top.

Figure 27.1 - Manifold tubes retaining bolt.

Allen wrench

on retainer bolt

First tube has larger hole

s

Item

Brick Size

Qty in Set

1

9 x 4-1/2 x 1-1/4” with hole

2

2

9 x 4 x 1-1/4” with cut

2

4-1/2 x x 1-1/4”

1

4

9 x 4-1/2 x 1-1/4”

12

5

9 x x 1-1/4”

6

9 x 1-1/2 x 1-1/4”

2

Use Part #82-0550 when ordering indi-

vidual brick and provide brick dimension

or copy this page and mark the desired

brick and take it to your authorized

dealer.