47

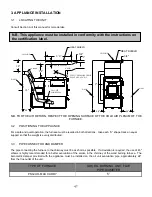

3. APPLIANCE INSTALLATION

3.1 LOCATING

THE

UNIT

Consult Section A of this manual for more details.

WALL

18''

18''

OIL UNIT

SMOKE PIPE

WALL

9''

HOT AIR PLENUM

CEILLING

6''

6' 0''

STATIC PRESSURE CHECK

POINT MIN. 0.20" W.C.

1"

CEILLING

WALL

24"

3/4"

HEAT SHIELD

24"

24"

3/4"

HEAT SHIELD

45° ELBOW

24''

8'' MIN.

N.B. FOR THE AIR RETURN, RESPECT THE OPENING SURFACE OF THE COLD AIR PLENUM OF THE

FURNACE.

3.2

POSITIONING THE APPLIANCE

For a safe and quiet operation, the furnace must be levelled in both directions. Give each “U” shape track an equal

support so that the weight is evenly distributed.

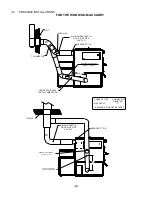

3.3

PIPE CONNECTOR AND DAMPER

The pipe connecting the furnace to the chimney must be as short as possible. If a deviation is required, the use of 45

o

elbows is highly recommended for a better evacuation of the smoke in the chimney of the wood burning furnace. The

barometric damper provided with the appliance must be installed on the oil unit evacuation pipe, approximately 24

"

from the flue outlet of the unit.

TYPE OF FURNACE

(UH) OIL BURNING UNIT FLUE

PIPE DIAMETER

PSG/ UH-MAX CADDY

5”

N.B. This appliance must be installed in conformity with the instructions on

the certification label.

Summary of Contents for MAX CADDY PF01101

Page 38: ...38 7 GENERAL ELECTRIC DIAGRAM WITH BECKETT OIL BURNER ...

Page 39: ...39 8 GENERAL ELECTRIC DIAGRAM WITH RIELLO OIL BURNER ...

Page 42: ...42 ...

Page 45: ......