18/22

NT 1401-X00 10 18 B200 Flow Control e

5. MAINTENANCE

5.1 Maintenance schedules

After every cleaning of the truck

Always run the compressor for 15 minutes to remove

any water that inadvertently gets into the piping. DO

NOT fog or introduce anti-corrosive liquids into the com-

pressor to prevent corrosion : Use of liquids in the com-

pressor will cause failure.

Weekly

1.

The compressor should be run for at least 15 minutes

to prevent moisture from collecting inside. This will

reduce the risk of corrosion damage to the compres-

sor and other equipment in the piping.

2.

Inspect and clean air filter. Inspect DAILY if operating

in dirty or severe environment. Check the condition of

the inlet filter hose for splits and tears. Replace or

repair as necessary.

3.

Inspect compressor, system piping and components.

Clean or repair as necessary.

4.

Check power transmission line.

5.

Check the air filter restriction indicator. When the indica-

tor turns red, replace the filter cartridge. Before repla-

cing the cartridge with a new one, clean the inside of

the filter's body with a clean damp cloth.

Per manufacturer’ s recommendations

Lubricate the universal seal (for B200 PS models).

Monthly

1.

Check the relief valve(s) for wear and proper settings.

Replace or adjust as necessary.

2.

Check that the check valve works properly, replace as

necessary.

3.

Check the oil level and complete if necessary.

Yearly :

1.

Check tightness of the 4 mounting nuts on the B200 PTO.

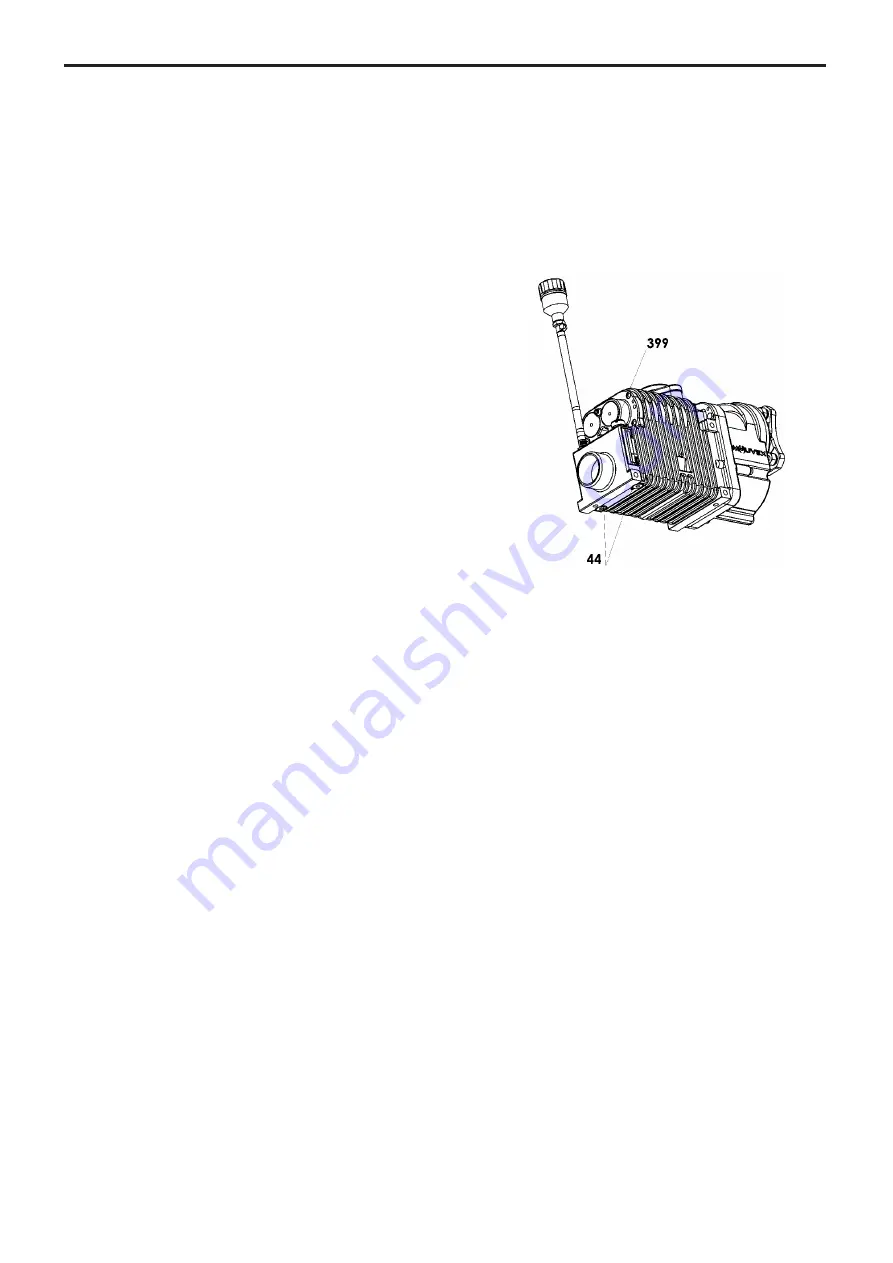

5.2 Compressor oil change

Oil recommendations : See § LUBRICANT RECOMMEN-

DATIONS.

Depending on the inclination of the compressor, remove

the lowest drain plug

44

.

Put plug

44

back into place and remove filling plug

399

and fill the compressor with new oil, as recommended in

§ LUBRICANT RECOMMENDATIONS.