6

S-PARK

- rev. 1.1_06_2020

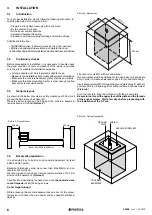

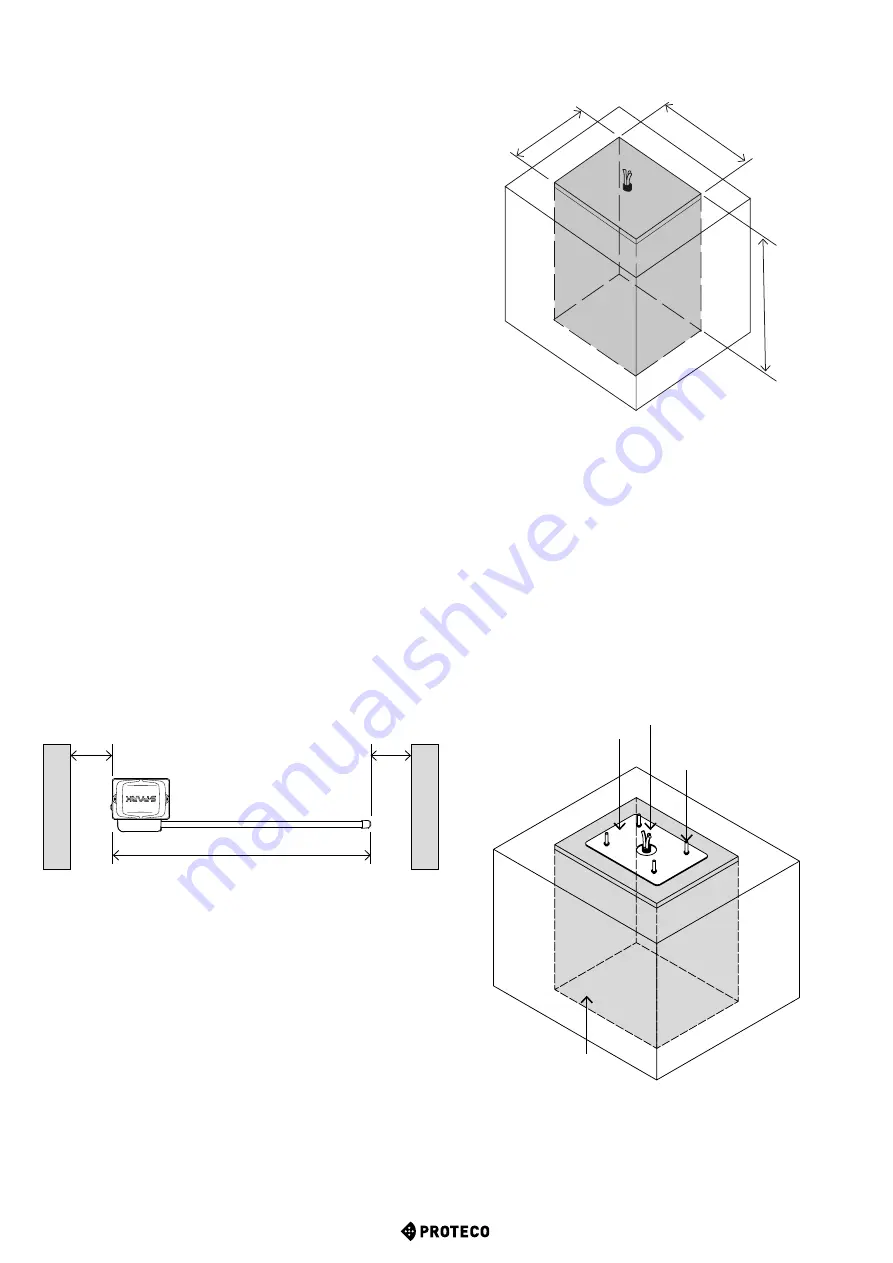

500 mm

500 mm

600 mm

500 mm

400 mm

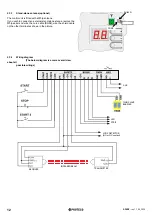

3. INSTALLATION

3.1

Introduction

For a proper installation, strictly follow the following procedure, re-

specting the below chronological order:

• Prepare a strong basement using ferro concrete.

• Fix the cabinet to ground.

• Fit the boom and accessories.

• Adjust and balance the spring.

• Proceed to self-learning programming and adjust settings.

Additional information:

• TWINNING function, it allows to manage two mirror barriers.

• RGB led singnalling strip available to complete the boom.

• Photocells and similar safety obstacle detection devices can be fitted.

3.2

Preliminary checks

Before proceeding to installation, it is necessary to double check

the good condition of every component of the barrier and make

sure the site is suitable for installation purposes.

• All components must be integral and suitable to use.

• Make sure the installation site complies with system’s dimensions.

• Make sure the concrete basement grants stability and solidity.

• Make sure the area around the barrier is clear enough to allow

eazy and safe manual operation.

3.3

General layout

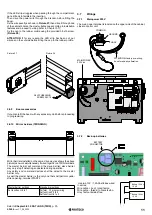

As shown in the below plan view, a safety clearance of 500 mm all

around the barrier area has been left.

While the boom length can be adjusted, the concrete basement

remains fixed as it is built

(Picture 2)

.

Boom from 4000 to 6000 mm

Picture 2: Overall layout

3.4

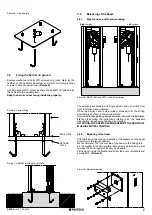

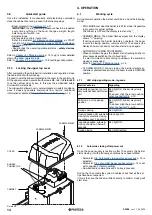

Basement preparation

It is absolutely key to build a solid concrete basement (at least

EN206 C25/30 proof).

Basement dimensions must be no less than 400x500mm and no

less than 600mm deep.

We recommend to consider an extra concrete surface of 200 mm

all around the basement.

(Picture 3)

Pay attention while arising the basement, since

the concrete work

cannot impede

to stud the fixing screws.

Do not forget wirings!

While preparing the concrete basement keep a duct of the proper

dimension to connect the main power and any possible additional

devices.

Picture 3: dimensions

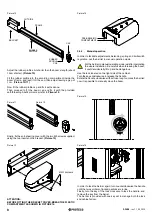

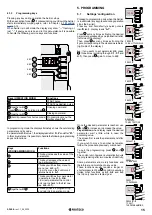

Fit anchor screws M10 with nut and washer.

Nut and washer must be positioned in the same way for each single

bolt, in order to create a balanced support for ground plate fixing.

Insert anchor screws M10 through the ground plate holes, fit washers

and nuts M10 to protruding part of anchor screws, as shown below.

(Picture 5)

Pour the concrete, flush the surface and fix the ground plate.

Be careful not to soil the upper face of the plate and the threads

of the anchor screws. Wait a few days before proceeding with

the installation of the S-Park.

Picture 4: Cabinet foundation

CONCRETE

BASEMENT

GROUND

PLATE

ANCHOR SCREW M10

WIRING