Pr

o

Minent

®

Page 32

Repairs

1

2

3

4

5

6

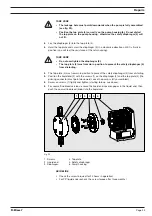

Fig. 29

1 Screws

4 Top plate

2 Liquid end

5 Safety diaphragm

3 Diaphragm

6 Pump housing

GUIDELINE

•

Check the screw torques after 24 hours in operation

•

For PP liquid ends check the screw torques again after three months.

Screw torques:

Liquid end Ø 70 mm:

2,5 to 3 Nm

Liquid end Ø 90 mm and Ø 100 mm: 4,5 to 5 Nm

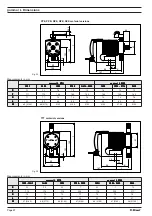

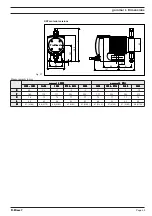

Liquid ends - types 0220, 0232 and 0420

S

Remove the liquid end (2) with screws from the top plate (4) and pump housing (6) about

5 mm - the screws should still be located in the holes but not in the top plate (4).

S

Hold the housing (6) in one hand and with the other hand, clamp the diaphragm (3) between

the liquid end (2) and the top plate (4); release the diaphragm (3) from the drive spindle with

a light anti-clockwise turn of the liquid end (2) and top plate (4).

S

Remove the liquid end (2) with screws (1) from of the diaphragm and unscrew completely

from the drive spindle.

S

Remove the top plate (4) from the housing (6).

S

Screw the new diaphragm (3) onto the drive spindle gently as far as it will go - otherwise the

gamma/ L will not meter correctly!

S

Unscrew the diaphragm (3) again.

S

Replace the top (4) plate onto the housing (6).

S

Check the condition of the safety diaphragm (5) and replace if necessary.

S

Push the safety diaphragm (5) only as far onto the drive axis until it lies flat on the pump

housing (6) – no further!

S

Screw the new diaphragm (3) carefully up to the stop on the drive axis – this must be exact

to ensure correct metering!

S

If not, start the pump and set the stroke length to 100 %.

S

When the pump is running, turn the diaphragm (3) slowly in a clockwise direction until the

four holes in the diaphragm are flush with those on the pump housing (6).

S

Hold the diaphragm (3) in this position, set the stroke length to 0 % and stop the pump.

S

Screw the diaphragm (3) tight once more.

S

Position the top plate (4) on the pump housing (6).