Pr

o

Minent

®

Page 29

Repairs

WARNING

Pumps used for radioactive materials cannot be returned to ProMinent after

use! They will not be accepted by ProMinent!

Repairs: These should only be carried out by qualified personnel (in accordance with Safety

section):

• Cleaning the valve

• Changing the diaphragm

WARNING

•

Always take suitable precautions when using hazardous chemicals!

•

Ensure equipment is de-pressurised

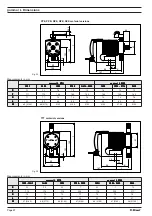

Cleaning the discharge valve (PP, PC, NP) for types 1000, 1005, 1605, 1601, 1602

GUIDELINE

•

Discharge and suction valves are different! Dismantle one after the other to

avoid confusion.

•

Only use new parts, which fit your valve (in shape and chemical resistance)!

•

The pump must be reset after replacing a valve.

S

Loosen the hose.

S

Unscrew the discharge valve from the liquid end and rinse thoroughly.

S

Remove the O-ring from the liquid end with a small screw driver.

S

Insert an Allen key or similar into the smaller hole of the pressure connector and push out

the valve inserts.

S

Remove the valve seats with a small screwdriver and allow the valve balls to drop out.

S

Clean all parts

S

Drop the valve balls into the valve seats and push on the valve inserts

S

Press the valve seats into the pressure connector with their smaller hole in the direction of

the flow (see direction of arrows on the fluting on the pressure connector)

S

Insert the O-ring into the liquid end

S

Screw the valve in as far as it will go

S

Secure the hose

Fig. 25

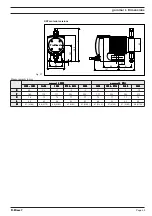

Cleaning the suction valve (PP, PC, NP) for types 1000, 1005, 1605, 1601, 1602

Dismantling, cleaning and reassembly of the suction valve is practically the same as for a

discharge valve.

Take care however that:

•

both valve inserts are actually identical

•

an additional spacer is found under the valve inserts

•

in the liquid end a shaped seal is used instead of an O-ring

•

the flow direction of the suction connection is reversed as for the pressure connector.

Fig. 26