Pr

o

Minent

®

Page 6

Assembly and Installation

6

Assembly and Installation

WARNING

•

The gamma/ L series dosing pumps must be commissioned exactly as

described in the operating instructions manual!

•

It is not permitted to assemble and install ProMinent

®

dosing pumps with

non-original parts unless these have been checked and recommended by

ProMinent.

•

Always depressurise tubing before working on the dosing pump. Empty and

rinse out the liquid end!

•

Never allow the dosing pump to operate when an discharge tube stop tap is

closed ! It may burst!

•

Remove all water from liquid end before commissioning or rinse with a

suitable cleaning agent if using chemicals that should not come into contact

with water!

•

Before unscrewing the control unit disconnect the mains lead from the

power supply!

•

Observe applicable national directives during installation!

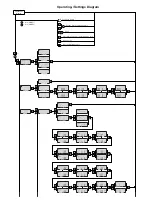

6.1

Assembling dosing pump

TAKE CARE

•

The gamma/ L should be fixed in such a way as to prevent vibration!

•

Suction and discharge valve must be upright (bleed valve in self-bleed liquid

ends)!

•

Ensure free access for operation and maintenance!

Assembling dosing pump

The base of the dosing pump must be mounted on a firm, horizontal surface.

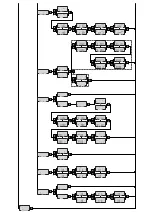

6.2

Assembling tubing

6.2.1

Installation for non-self bleeding pumps

CAUTION

•

Tubing must be free from stress and kinks when fitted!

•

When dosing extremely aggressive or hazardous chemicals it is advisable to

install a bleed valve that feeds back to the container and isolation valves on

the prime and discharge sides.

•

In order to ensure connections are fast, use correctly sized clamping rings

and nozzle unions!

•

Use only original hoses with specified dimensions and wall-thicknesses!

•

Do not exceed maximum permissible priming pressure (see section 14)!

•

It is imperative that the maximum permissible operating pressure is not

exceeded (see section 14 and appendix documentation)!

GUIDELINE

The tubing should be attached in such a way as to allow lateral detachment of the

gamma/ L and the liquid end if necessary!