60 Gallon Single Stage Stationary Air Compressor

11

Visit www.princessauto.com for more information

8475006

V 1.6

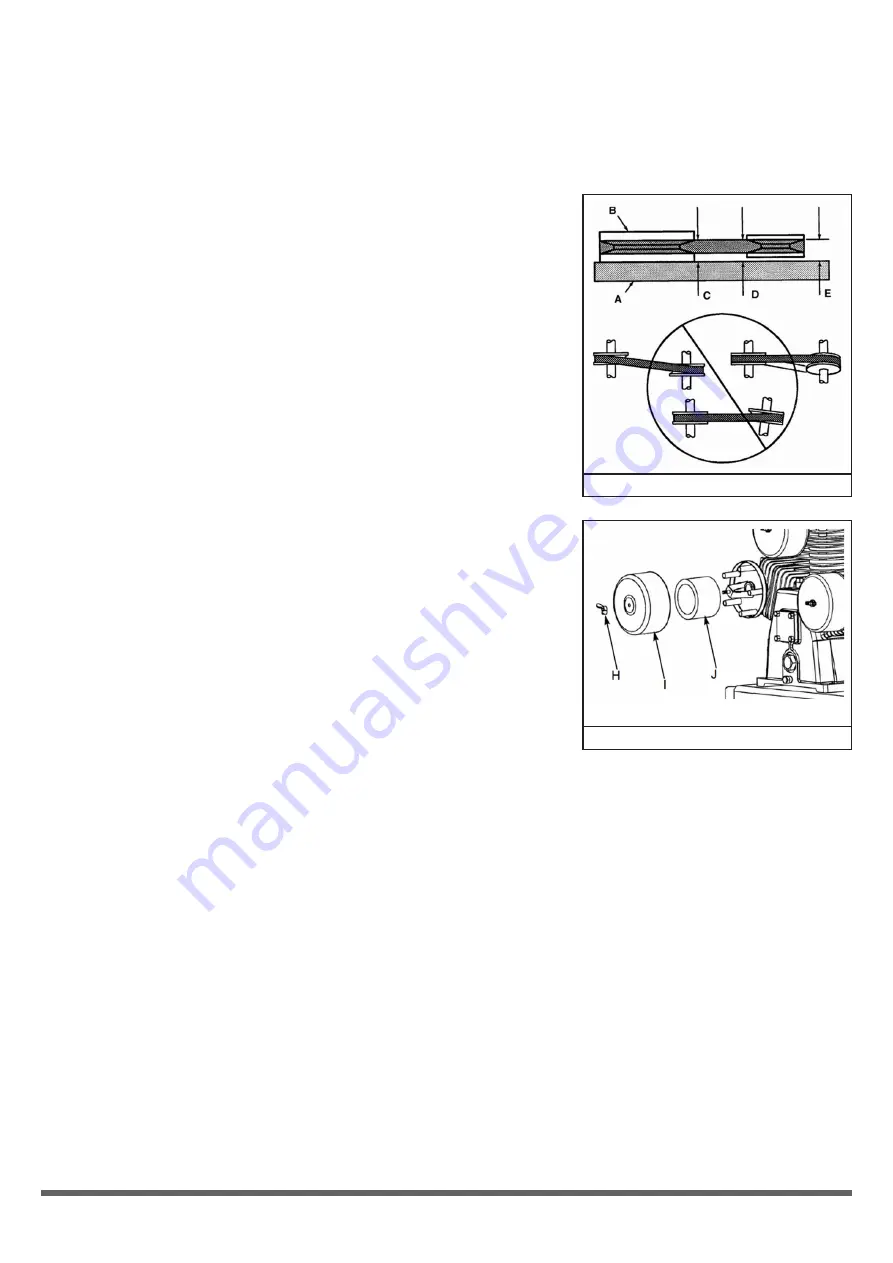

PULLEY ALIGNMENT

To check pulley alignment, remove the belt guard and place a straightedge (A) against the pump

flywheel (B) (Fig. 8). Measure and record the distance from the straightedge to the edge of the

drive belt at point C. Then measure the distance from the straightedge to the edge of the drive

belt again at points D and E. Both distances should be the same as at point C. If either D or E

are different from C, there is a misalignment which must be

corrected before the compressor is run.

To correct a pulley misalignment, use the

following procedure.

1. Remove the belt guard.

2. Loosen the motor mounting bolts.

3. Loosen the set screw on the motor pulley.

4. Align the motor pulley with the pump flywheel

(C = D = E).

5. Retighten the motor pulley set screw.

6. Adjust the proper belt tension.

7. Retighten the motor mounting bolts.

8. Reinstall the belt guard. All moving parts must

be guarded.

CLEANING THE AIR FILTER

A dirty air filter will reduce the compressor’s performance and

life. To avoid any internal contamination of the pump, the filter

should be cleaned frequently and replaced on a regular basis.

Remove the wing nut (H) and filter canister (I) to access the

filter (J).

Felt filters should be cleaned in warm, soapy water, rinsed and

allowed to air dry before reinstallation. Paper filters should be

replaced when dirty. Do not allow the filter to become filled with

dirt or paint. Replace the filter if it becomes filled with paint.

TESTING FOR LEAKS

Check that all connections are tight. A small leak in any of the

hoses, transfer tubes or pipe connections will substantially

reduce the performance of your air compressor. Locate a leak by spraying a small amount of soapy

water around the area of the suspected leak. Repair or replace the faulty component if bubbles

appear. Do not over tighten any connections.

STORAGE

Before storing the compressor for a prolonged period, use an air blowgun to clean all dust and

debris from the compressor. Disconnect the power cord and coil it up on the handle. Open the

drain valve to release all pressure from the tank. This will also drain all moisture from the tank.

Clean the filter element and filter housing; replace the element if necessary. Drain the oil from the

pump crankcase and replace it with new oil. Cover the entire unit to protect it from moisture

and dust.

Fig. 8

Fig. 9

Summary of Contents for 8475006

Page 20: ......