Troubleshooting and Maintenance

47

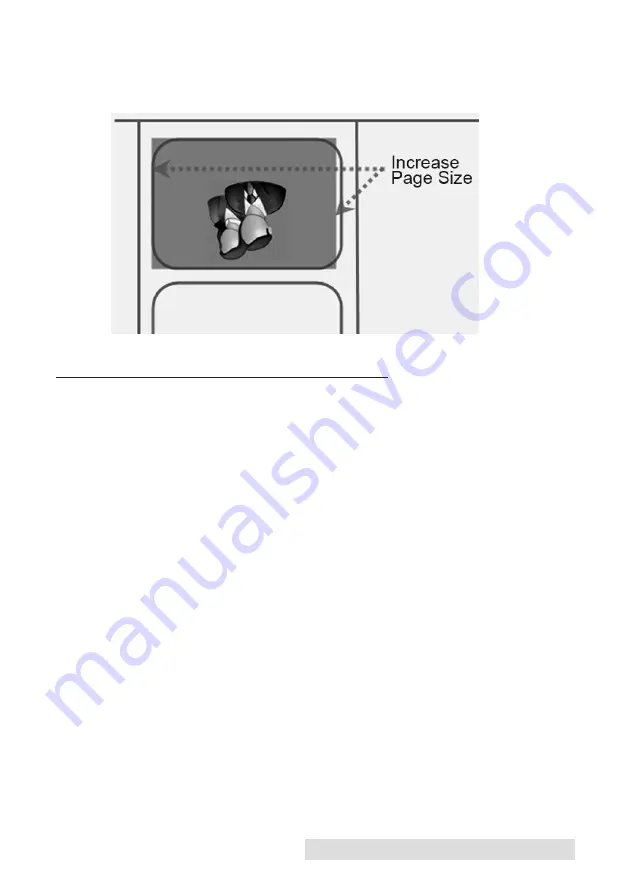

the opposite side. This indicates that the page size needs to

be increased. Increase the page size through the printer

preferences enough to cover the label.

B. SOLVING PRINT QUALITY PROBLEMS

Many factors can affect the quality of the print. The following

are listed in order from most likely to least likely:

1.

Quality Setting.

Change your quality setting. The lowest

(and fastest printing) quality may not be sufficient for

many photos or graphics. The highest quality setting may

cause ink to bleed on certain graphics in combination with

certain label stock. Increasing the quality increases print

time because the printer makes more horizontal move-

ments across the label.

2.

Clean the Printhead.

Run an automatic printhead cleaning

print or manually clean the printhead as described in

Section 5F .

3.

Change Cartridge.

Try a new cartridge. Make sure that the

ink cartridge has ink remaining. Check the ink levels via

the Status Monitor.

4.

Align Printhead.

Normally, printhead alignment is

only necessary after changing a printhead. However, in

certain cases, running the alignment again can improve

print quality. Align the printhead by opening the PTStatus

Monitor. Click on the Align Printhead button on the

Cartridge Utilities Tab (second tab). Follow the onscreen

prompts to load your paper for alignment.