15

Function Descriptions

Counters

NOTE: All counters are automatically stored at

power down.

The PressCam 8 provides four types of counters: Stroke,

Batch, Quality, and Part. When programmed properly a

counter will increment each time a part is ejected from

the machine. When the programmed value is met, the

controller will initiate an action.

Stroke Count.

The Stroke Counter is used to indicate

the total number of strokes that has occurred since the

last stroke counter reset. This number increases by

one every time the resolver passes 340° regardless of

job changes or faults. You can reset this count in RUN

or PROG modes.

Part Count.

This box has two

fi

elds—In the upper right,

a

Part Increment

fi

eld which represents the number of

parts produced per stroke, and a

Part Count

fi

eld which

shows the number of parts produced. You can only set

the

Part Increment

fi

eld in PROG mode.

The programmer can set the number of how many parts

are being counted or produced on each stroke of the

press. They can set the unit to count 0 through 4. If the

unit is set to zero, then the PressCam 8 will not increment

the Part Count, Batch Count or the Quality Count.

You can reset the

Part Count

in RUN or PROG modes.

NOTE: The Part count automatically increments

off the Stroke count, unless DIE #7 is activated as

a “Momentary” die type with different “Begin” and

“End” angles. In this case, you will need to provide a

sensor input to DIE #7 to increment the Part count.

The Part Increment

fi

eld is used by the Batch and Quality

counters. Resetting the Part Counter will not affect the

other counters.

Batch Size.

The Batch Size determines when the Batch

Count increments. This can only be changed in PROG

mode. The Batch Size is based on the Part Increment

fi

eld size (the upper right of the Part counter box)

Batch Count.

The Batch Counter is used to indicate the

number of batches completed and/or stop the machine

when a batch is complete (using Output Relay #12).

This can be reset in RUN or PROG modes.

NOTE: Batch Counter only works when Part Count

is wired to a sensor and is activated.

Quality Count.

The Quality Counter is used to stop the

machine when the parts produced reaches the value

in the “Quality Count”. This is used to indicate to the

operator that the last part should be checked for quality

purposes based on your company’s SPC requirements.

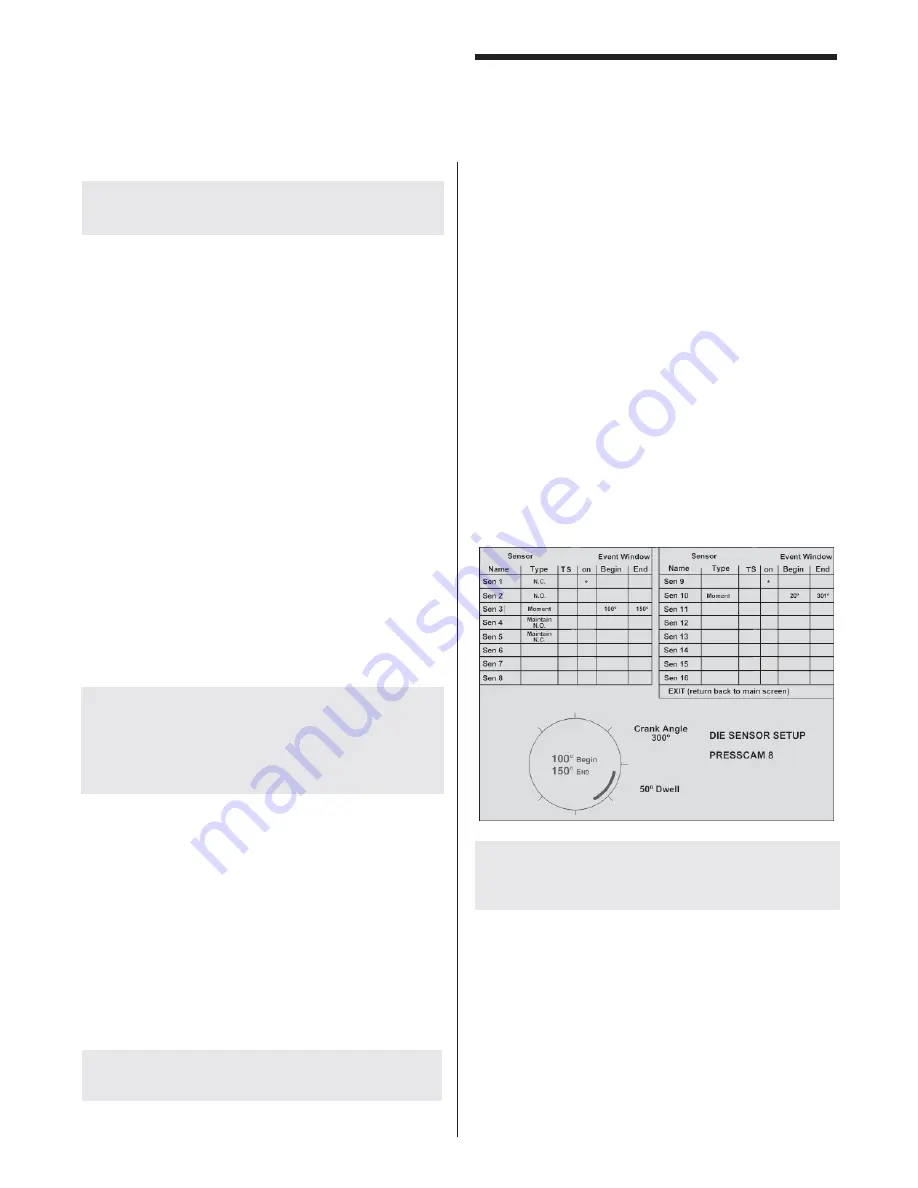

Die Sensor Setup

This function is used by the programmer to program any

one of the sixteen die protection inputs and can only be

highlighted and accessed in the PROG mode.

Die Sensor Inputs 1 to 16 can have custom selected

names. The names can only be changed while in PROG

mode (refer to the “Job Selection” section for details

on how to enter in names). If Sensor #7 is setup for

“Momentary” and has a valid angle window, the computer

will use this input to increment the Parts Counter. This

is why the default name is “Part Cnt.”

To change the name of a Die Sensor Input, refer to “Job

Selection” section.

NOTE: In PROG mode, the PressCam 8 will not

shut down on a die fault but will limit you to ten

cycles.

Main Screen Die Sensor Display

When a die sensor input faults an “f” is indicated. When

in the die window the faulted sensor shows “F”.

A faulted sensor also shows the last CLOSE-OPEN

angles seen by the computer, to help determine if and

where the sensor changed states.

If the sensor faults, but the angles shown are within the

die settings, then the sensor did not change states the

last cycle.

Summary of Contents for PressCam 8

Page 1: ...PressCam 8 Installation Operations Manual ...

Page 2: ...Rev 5 0 ...

Page 14: ...6 Internal Wiring Diagram 28 101 System Installation ...

Page 15: ...7 Control Box Dimensions 28 102 System Installation ...

Page 16: ...8 Panel Cut Out Dimensions 28 103 System Installation ...

Page 17: ...9 Control Panel Dimensions 28 104 System Installation ...

Page 18: ...10 System Installation External Wiring Diagram 28 105 ...

Page 19: ...11 System Installation I O Board Dimensions 28 106 ...

Page 44: ...36 Tonnage Load Monitor optional Installation T400 Installation ...