Page 14

For technical questions, please call 1-888-866-5797.

ITEM 61594

SAFETY

Op

ERA

TION

M

AINTENANCE

SETU

p

Break-in period:

a. Breaking-in the engine will help to ensure proper equipment and engine operation.

b. The operational break-in period will last about 3 hours of use. During this period:

• Do not apply a heavy load to the equipment.

• Do not operate the engine at its maximum speed.

c. The maintenance break-in period will last about 20 hours of use.

• Change the engine oil after this period.

Under normal operating conditions subsequent maintenance follows the

schedule explained in the

Maintenance

section on page 18.

Log Splitter Operating Instructions

1.

Check the hydraulic fluid level; fill as necessary.

2. Ensure that the Support Leg is down and place

wheel chocks (not included) on each side of the

wheels to keep the Log Splitter from moving.

3. Follow procedures in previous

section to start the engine.

IMpORTANT:

Hydraulic fluid temperature must be

above 10° F (-12° C) before operating the Log Splitter

or damage to the hydraulic pump may result. If outdoor

temperature is below 32° F (0° C) use the Control Handle

to cycle the Cutting Wedge forward and back several

times to warm the hydraulic fluid before splitting wood.

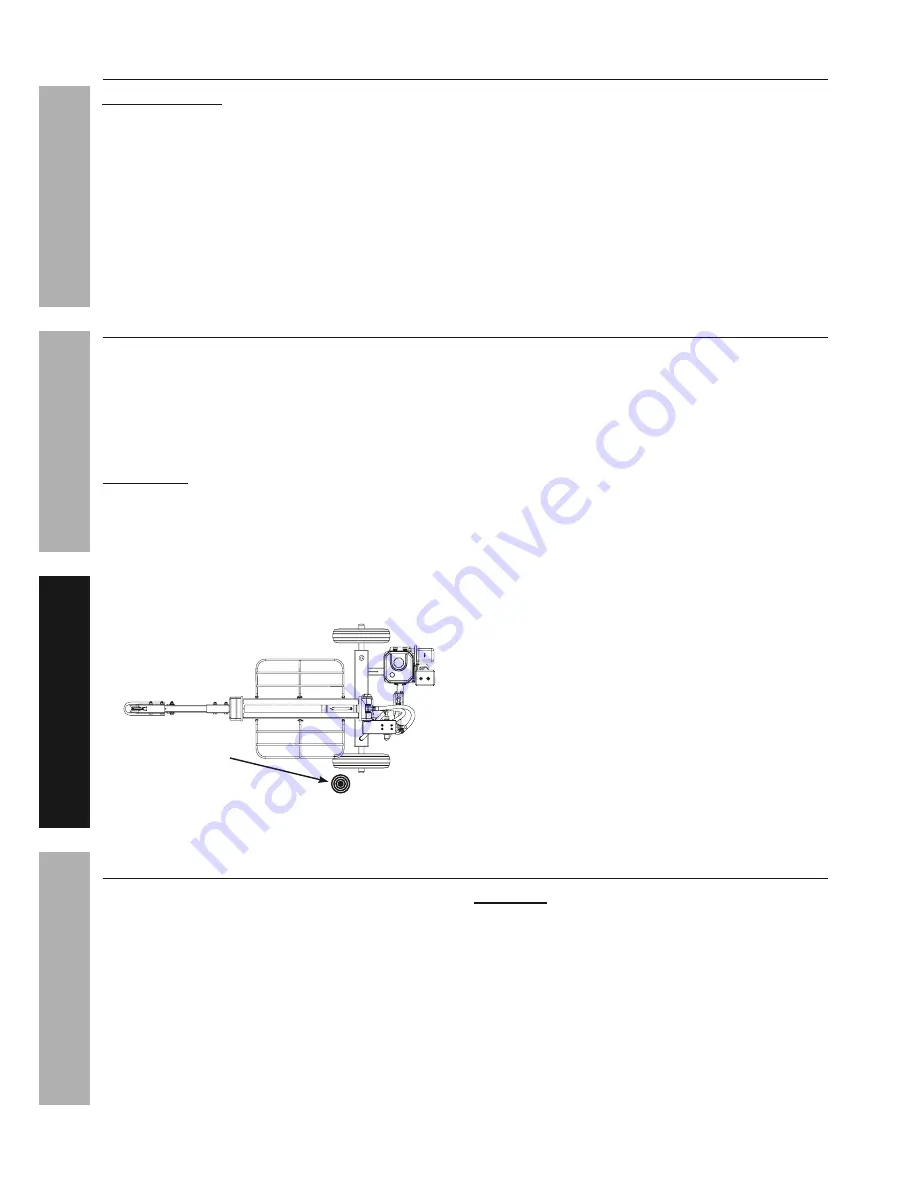

4. Stand in the correct operator position as shown

in Figure A when operating the Log Splitter.

Correct Operator

position

Figure A: Operator position

5. Hold the rounded, bark side of log and position

it lengthwise in the direction of the grain on the

Beam of the Splitter between the Log Cradles.

Place one end of log against the end plate.

6. The log must be stable so that it will split properly.

Hold the top of the log at its center, if safe to do so.

Release log once Cutting Wedge engages it.

7. Push the Control Handle forward to drive the

Cutting Wedge forward into the log, splitting it.

8. Remove split log pieces and place the next

log against the opposite end plate.

9. Push the Control Handle backward to

drive the Cutting Wedge in the opposite

direction into the log, splitting it.

10. Turn off the Log Splitter engine after use. Clean,

then cover the tool and store in a dry, level,

well-ventilated area out of reach of children.

Removing a Stuck Log

A log that is too stringy or tough to split completely

can become stuck on the Cutting Wedge if the

Wedge becomes embedded in the log and

the log doesn’t completely split and separate.

If this happens, follow the directions below.

1. Relieve pressure on log and end plate

by retracting Cutting Wedge slightly.

2. Turn the Engine Switch to its “OFF” position

and disconnect the spark plug cap.

3. Remove the stuck log from the Cutting Wedge

manually with a sledge hammer and pry bar.

WARNING!

Be extremely careful when removing

the log as pieces may fly off as they separate from

the Wedge. Never attempt to remove a stuck log

by using the hydraulic force of the Log Splitter,

modifying the Log Splitter, or adding attachments

to the Log Splitter. Personal injury could result

from log or metal pieces flying out at high speed,

or the Log Splitter could become damaged.

4. Do not attempt to re-split a stuck log once it

has been removed from the Wedge. Manually

split with a maul, or cut with a chainsaw.

Starting the Engine (continued)