13

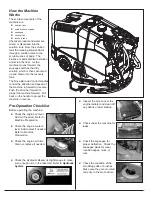

Filling the Solution Tank

1. Start the machine and move to the dispenser station or

other filling site.

2. Put the throttle in the idle position and turn the unit off

by turning the key-switch off.

3. Open the solution

tank cover and fill

from a dispenser

with cleaning

solution. If hand-

mixing chemical

products, fill

approximately 80%

of the solution tank

with water. Pour

the required

amount of cleaning

chemical product

into the solution

tank fill opening.

Continue filling the

solution tank to 1

inch (25 mm)

below the bottom of the solution fill opening.

NOTE:

Always read and follow manufacturers label

instructions for use and handling of chemical products.

NOTE:

Floor condition, water condition, amount of soilage,

types of soilage, and pad/brush action all play an

important role in determining the type and dilution ratio

of cleaning chemical product. For specific

recommendations, contact your Amano Pioneer Eclipse

Authorized Distributor.

WARNING:

Flammable materials can cause an explosion

or fire. Do not use flammable materials in tanks.

Normal Scrubbing

z

Pick up trash and oversized debris before scrubbing.

Pick up pieces of wire, string, etc., which could become

wrapped around the scrub brush and damage the

machine.

z

Plan the scrubbing in advance. Try to arrange long runs

with minimum stopping and starting. Do an entire floor

or section at one time.

z

Try to scrub as straight a path as possible. Avoid

bumping into posts or scraping the sides of the

machine. When scrubbing dead end aisles, start at the

closed end of the aisle and scrub your way out.

Overlap the scrub paths by a few inches (centimeters).

z

If you experience unacceptable scrubbing performance,

stop scrubbing and refer to

Machine Troubleshooting

.

1. Start the machine and drive to the area to be scrubbed.

2. Press the top of

the scrub switch to

activate the

scrubbing function.

The scrub brushes

will lower and turn

on automatically

when the machine

moves.

3. Press the top of

the vacuum

switch. The

squeegee

automatically

lowers and the

vacuum system

turns on.

4. Adjust the solution

flow to the floor as

needed.

5. Push the drive bar

forward to drive

the machine

forward and scrub

as required.

WARNING:

Flammable materials or reactive metals can

cause an explosion or fire. Do not pickup.

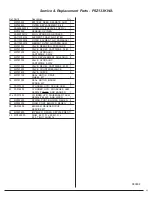

Summary of Contents for Z1 PSZ133KWA

Page 3: ......

Page 19: ...16 Machine Troubleshooting...

Page 20: ...17 Maintenance...

Page 27: ...Service Replacement Parts PSZ133KWA 031708 24...

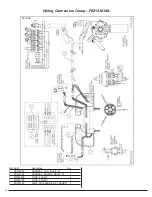

Page 29: ...26 Wiring Schematic PSZ133KWA SAFE SENSE FOR MACHINES SERIAL NUMBER 62233 AND EARLIER 031708...

Page 30: ...27 Wiring Schematic PSZ133KWA ECO SENSE FOR MACHINES SERIAL NUMBER 62420 AND LATER 031708...

Page 32: ...29 Hydraulic Schematic PSZ133KWA 031808...

Page 33: ...30 Hydraulic Hose Connection Group PSZ133KWA 031808...

Page 35: ...32 Frame Wheel Group PSZ133KWA 031808...

Page 37: ...34 Power Group Engine PSZ133KWA 031808...

Page 39: ...36 Hydraulic Reservoir PSZ133KWA 031808...

Page 41: ...38 Airbox PSZ133KWA 031808...

Page 43: ...40 LP Regulator PSZ133KWA 031808...

Page 45: ...42 Scrub Deck Group PSZ133KWA 052308...

Page 47: ...44 Squeegee Lift Group PSZ133KWA 031808...

Page 53: ...50 Solution Tank PSZ133KWA 031808...

Page 55: ...Recovery Tank PSZ133KWA 52 030808...

Page 57: ...54 Engine Cover PSZ133KWA 031908...

Page 59: ...Squeegee 45 PSZ133KWA 56 031908...

Page 61: ...58 Control Panel Bulkhead Group PSZ133KWA 031908...

Page 63: ...60 Operational Controls PSZ133KWA 031908...

Page 67: ...64 Relay and Timer Group PSZ133KWA 031908...

Page 73: ...70...