3

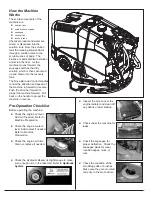

CAUTION!

Do not operate machine unless trained and

authorized. Do no operate machine unless you have

read and understand the operation manual. Do not

operate machine in flammable or explosive areas.

CAUTION!

Before starting machine ensure all safety

devices are in place and functioning properly. Before

starting machine check for proper operation.

CAUTION!

When using machine, go slowly on inclines or

slippery surfaces. Use care when operating machine in

reverse. Follow all manufacturers instructions on

chemical product containers when handling, mixing, or

using chemical products.

CAUTION!

When servicing machine, stay clear of moving

parts. Do not wear loose clothing when working on

machine. Block machine wheels before raising or

jacking up machine. Use hoist stands that will support

the weight of the machine. Empty tanks before jacking

up or raising machine. Wear eye and ear protection

when using pressurized air or water. Disconnect battery

connections before servicing machine. Use only

replacement parts supplied by Amano Pioneer Eclipse

or a Amano Pioneer Eclipse Authorized Distributor or

Service Center.

CAUTION!

When loading or unloading machine onto or off

a truck or trailer, turn machine OFF. Only use a truck or

trailer that will support the weight of the machine to

transport. Do not push the machine onto or off a truck

or trailer unless the load height is 15 in (380mm) or

less from the ground. Use a winch. Block machine

wheels when transporting. Tie the machine down

securely to truck or trailer when transporting. Empty

tanks before transporting.

This machine is manufactured for

commercial use only.

This machine is designed and manufactured for indoor use

in scrubbing dirt and dust from hard floor surfaces. Amano

Pioneer Eclipse does not recommend use of this machine

in any environment other than an indoor environment.

Propane powered floor equipment is designed and

manufactured for commercial floor cleaning only. These

machines are designed to clean most modern types of

floors including composition tile, stone, marble, terrazzo,

and resilient floor covering, and some coated wood floors.

Even though NFPA 58 8-4.5 says ...”these machines shall

be permitted to be used in buildings frequented by the

public, including the times when such buildings are

occupied by the public,” Amano Pioneer Eclipse suggests

usage when occupancy of a given work area is minimal.

These machines should not be used:

z

in nursing homes, hospitals, day-care centers, etc.

z

by unqualified or untrained personnel.

z

unless properly maintained and adjusted.

z

on areas with obstructions such as thresholds, floor

outlet boxes, etc.

z

in areas where loose tile or other objects are present.

z

in rooms without proper ventilation.

Refueling and Storage of Fuel

Cylinders

Amano Pioneer Eclipse uses the 20 lb. capacity aluminum

or steel Safe-Fill

®

cylinder which meets the DOT 4E240

standards. These cylinders are also listed by UL. Filling

should be done

ONLY

by a qualified propane dealer.

FILL

THROUGH THE SERVICE VALVE ONLY

. A properly filled

cylinder should not exceed 80% of the rated capacity.

DO NOT

attempt Safe-Fill cylinder repair. Return the

cylinder to your propane dealer if repair is necessary.

Please note that DOT regulations prohibit shipping of

cylinders after the cylinder has been filled with propane.

When not in use, cylinders always should be stored

outside in an upright position in a secure, tamper-proof,

steel mesh storage cabinet. This cabinet may be located

next to the building but with at least five feet (1.5 m) of

space between the cabinet and the nearest building

opening (door or window).

The National Fire Protection Association (NFPA) Standard

for Storage and Handling of LP Gas is the appropriate

authority for safe propane use. A copy of this publication is

available through the National Fire Protection Association

in Quincy, MA (1-800-344-3555).

Canadian Safety Regulations

1. A sign indicating “NO SMOKING” shall be

permanently displayed at the storage area. The sign

shall be in accordance with the sign required in Clause

10.12.3 of CAN/CGA-B149.2-M91, Propane Installation

Code.

2. When the cylinder is attached to the floor

maintenance machine for use, the operator shall not

leave the unit unattended except for short periods of

time such as rest stops, washroom or meal stops.

3. The requirements of 1.10.1 (e) and (g) do not apply in

industrial buildings.

4. A floor maintenance machine shall only be used in

buildings:

a) provided with continuous mechanical ventilation that

removes the products of combustion to the outdoors of not

less than 300 CFM for each 10,000 Btu-hr input or fraction

thereof.

b) provided with natural ventilation of not less than 300 CFM

for each 10,000 Btu-hr input or fraction thereof, based on a

maximum of one quarter air exchange per hour for the net

building volume.

5. The owner of a floor maintenance machine shall ensure

Summary of Contents for Z1 PSZ133KWA

Page 3: ......

Page 19: ...16 Machine Troubleshooting...

Page 20: ...17 Maintenance...

Page 27: ...Service Replacement Parts PSZ133KWA 031708 24...

Page 29: ...26 Wiring Schematic PSZ133KWA SAFE SENSE FOR MACHINES SERIAL NUMBER 62233 AND EARLIER 031708...

Page 30: ...27 Wiring Schematic PSZ133KWA ECO SENSE FOR MACHINES SERIAL NUMBER 62420 AND LATER 031708...

Page 32: ...29 Hydraulic Schematic PSZ133KWA 031808...

Page 33: ...30 Hydraulic Hose Connection Group PSZ133KWA 031808...

Page 35: ...32 Frame Wheel Group PSZ133KWA 031808...

Page 37: ...34 Power Group Engine PSZ133KWA 031808...

Page 39: ...36 Hydraulic Reservoir PSZ133KWA 031808...

Page 41: ...38 Airbox PSZ133KWA 031808...

Page 43: ...40 LP Regulator PSZ133KWA 031808...

Page 45: ...42 Scrub Deck Group PSZ133KWA 052308...

Page 47: ...44 Squeegee Lift Group PSZ133KWA 031808...

Page 53: ...50 Solution Tank PSZ133KWA 031808...

Page 55: ...Recovery Tank PSZ133KWA 52 030808...

Page 57: ...54 Engine Cover PSZ133KWA 031908...

Page 59: ...Squeegee 45 PSZ133KWA 56 031908...

Page 61: ...58 Control Panel Bulkhead Group PSZ133KWA 031908...

Page 63: ...60 Operational Controls PSZ133KWA 031908...

Page 67: ...64 Relay and Timer Group PSZ133KWA 031908...

Page 73: ...70...