Power-Flo Pumps & Systems • 877-24PUMPS • www.powerfl opumps.com

11

Bearings & Inner Seal -

Remove seal (19)

rotating member and spring from rotor

shaft. Press stationary from intermediate

(21) with fl at screwdriver. Examine all seal

parts. Inspect contact faces for signs of

uneven wear tracks on stationary, chips

and scratches on either seal face.

DO

NOT interchange seal components,

replace the entire shaft seal (19).

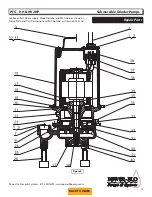

Remove retaining ring (39) from shaft.

Using a wheel puller or arbor press

remove bearing (18) from shaft. Remove

upper motor bearing from shaft with a

bearing puller. (See Figure 3)

Check sleeve bearing (23) for excessive

wear, if replacement is required, press

sleeve from intermediate coupling (21).

IMPORTANT! - All parts must be

clean before reassembly.

Handle seal parts with extreme

care. DO NOT damage lapped

surfaces.

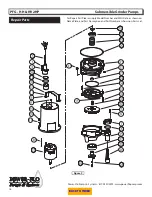

Reassembly

Bearings -

Be careful not to damage

the rotor shaft when replacing bearings.

Using an arbor press, hold the rotor and

press the upper bearing on the rotor

shaft, applying force to the inner race of

the bearing only. Replace upper retaing

ring onto rotor shaft. In the same manner

replace lower bearing (18) onto rotor

shaft. Place lower retaining ring (39) onto

shaft.

Inner Seal -

Clean and oil seal cavity

in intermediate coupling (21). Lightly

oil

(Do not use grease)

outer surface

of stationary member. Press seal’s

(19) stationary member firmly into

intermediate coupling (21), using a seal

tool or pipe. Nothing should come in

contact with the seal face except the seal

tool. Be sure the stationary is in straight.

Place seal’s (19) retaining ring and spring

over shaft until seated on shaft shoulder.

Slide a bullet tool over rotor shaft threads.

Lightly oil

(Do not use grease)

shaft,

bullet, and inner surface of bellows on

rotating member, with fi nished end away

from motor, slide rotating member over

bullet and onto shaft until it engages

spring.

Make sure spring is seated in retaining

ring and spring is lined up on rotating

member and not cocked or resting on

bellows tail. (See Figure 3)

Motor -

Slide rotor/shaft with bearing

(18) and seal parts (19) into intermediate

coupling (21) until bearing seats into

intermediate coupling. Install retaining

ring (39) into intermediate coupling (21).

Place motor stator over rotor, lining up

motor bolts with holes in intermediate

coupling (21). Place end bell on top of

motor and insert motor bolts and torque

to 17 in-lbs.

Set square ring (20) in grove on

intermediate coupling (21). Attach

ground wire (36) to end bell if removed.

Pull wires through opening in top of

motor housing (15) while lowering motor

housing onto intermediate coupling

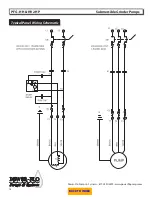

(21). Connect wires to pins on bottom

of terminal block (37) as noted at

disassembly and/or see wiring digrams in

Figure 7.

Lubricate o-ring (9) with dielectric oil

and slide terminal block (37) back into

housing (15). Be sure terminal block is

engaged and install retaining ring (38).

Place cap screws (35) with lockwashers

(11) through housing (15) into

intermediate coupling (21) and tighten.

(See Figure 4)

Service

Figure 3

PFG - HH & HV 2HP

Submersible Grinder Pumps

BACK TO INDEX