Power-Flo Pumps & Systems • 877-24PUMPS • www.powerfl opumps.com

2

General Safety Information

Model Number

MFG Date

AMPS

VOLTAGE

PHASE

60 Hz HP

877-24 PUMPS

www.powerflopumps.com

C

US

® Power-Flo is a registered trademark of Power-Flo Technologies Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Alteration Rights Reserved. 11/2007 - 3/08, 9/08, 6/09, 9/09

IMPORTANT!

Prior to installation, record Model Number, MFG Date, Amps, Voltage,

Phase and HP, from pump name plate for future reference. Also record the

Voltage and Current Readings at Startup:

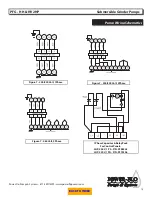

1 Phase Models

3 Phase Models

Amps:

Amps L1-2:

Volts L1-2:

Volts:

Amps L2-3:

Volts L2-3:

Amps L3-1:

Volts L3-1:

Before installation, read the following

instructions carefully. Failure to follow

instruction and Safety information

could cause serious bodily injury,

death and/or property damage. Each

Power-Flo pump is individually factory

tested to insure proper performance.

Closely following these instructions will

eliminate potential operating problems,

assuring years of trouble-free service.

ALL RETURNED

PRODUCTS MUST BE

CLEANED, SANITIZED,

OR RECONTAMINATED

PRIOR TO SHIPMENT,

TO INSURE EMPLOYEES WILL NOT

BE EXPOSED TO HEALTH HAZARDS

IN HANDLING SAID MATERIAL.

ALL APPLICABLE LAWS AND

REGULATIONS SHALL APPLY.

DO

NOT

introduced into any sewer,

either directly, or through a kitchen

waste disposal unit or toilet:

Seafood

Shells, Aquarium Gravel, Cat Litter,

Plastic Objects (toys, utensils, etc.),

Sanitary Napkins or Tampons, Diapers,

Rags, Disposable Wipes or Cloth,

Medications, Flammable Material, Oil or

Grease, Strong Chemicals, Gasoline

.

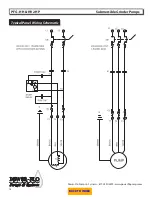

• Risk of electric shock. To reduce risk of

electric shock, always disconnect pump

from power source before handling.

Lock out power & tag.

• Installation must be in accordance

with the National Electric Code and all

applicable state and local codes.

• Installation and servicing is to be

conducted by qualifi ed personnel.

• These pumps are NOT to be installed

in locations classifi ed as hazardous in

accordance with the National Electric

Code, ANSI/NFPA 70.

• Keep clear of suction and discharge

openings. Do not insert fi ngers in

pump with power connected.

• Always wear eye protection when

working on pumps.

•

DO NOT

use power cord to lift pump.

Protect cable from cuts and punctures.

Do not handle power cable with wet

hands.

• Do not us these pumps in water over

145˚F. Consult Power-Flo for high

temperature pump models.

• Pumps build up heat and pressure

during operation-allow time for pumps

to cool before handling or servicing.

This pump is

NOT

intended for

use in swimming pools or any

body of water with human

contact. Pumps when used as a

decorative water fountain

pump

MUST

be used in circuit

protected by a Ground Fault

Interrupter.

• Bronze/brass fi tted pumps may contain

levels higher than considered safe for

potable water systems. Government

agencies have determined that leaded

copper alloys should not be used in

potable water applications.

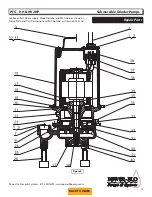

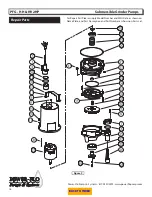

PFG - HH & HV 2HP

Submersible Grinder Pumps

BACK TO INDEX