Power-Flo Pumps & Systems • 877-24PUMPS • www.powerfl opumps.com

12

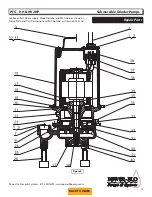

Power Cable Connection -

Check power

cord (3) for cracks or damage and replace

if required. Insert female end of cord

plug into housing bore

aligning timing

mark

with hole in terminal block (37)

see Figure (5). Compress cord plug with

compression flange by tightening cap

screws (1) with lock washers (2) into the

housing (15). Torque to 132 in-lbs.

Seal Plate -

Lubricate and set square

ring (24) in bottom groove of seal plate

(31). Place seal plate (31) over shaft and

onto intermediate coupling (21), being

sure square ring (24) is not twisted and

in the groove. Place two capscrews (32)

with lockwashers (11) into seal plate and

torque to 6.5 ft/lbs.

Outer Seal -

Clean and oil stationary

seal cavity in seal plate (31). Slide seal

guide tool over motor shaft. Lightly

oil

(Do not use grease)

outer surface

of seal’s (33) stationary member. Press

stationary fi rmly into seal plate (31) using

a seal pusher tool. Be sure the stationary

member is in straight. Nothing but the

seal tool is to come in contact with seal

face. (See Figure 6)

IMPORTANT ! Do not hammer

on the seal pusher. It will

damage the seal face.

With seal guide tool over motor shaft,

Lightly oil

(Do not use grease)

guide,

shaft and inner surface of bellows on

rotating seal. With lapped surface of

rotating member facing inward toward

stationary, slide rotating member over

guide and onto shaft, using seal pusher

tool, until lapped faces of stationary and

rotating seal are together. Place spring

over shaft and rotating member.

Be sure it is seated on the retainer and

not cocked or resting on bellows tail.

Impeller -

Place impeller (30) on motor

shaft, with machined step fi tting inside

the inside diameter of seal spring, by

turning clockwise while holding shaft

stationary with screwdriver.

Shredding Ring -

Install shredding ring

(27) into volute with the use of an arbor

press.

Volute -

Place volute (25) on seal plate

(31). Place nuts (41) with lockwashers

(11) onto studs (34) and torque evenly to

11 ft/lbs.

Note: Discharge must line up with notch

in motor housing.

Cutter -

Screw radial cutter (29) onto

shaft, turning it clockwise while holding

the shaft stationary with a screwdriver.

The radial cutter (29) should be fl ush with

shredding ring (27), on suction side to

within ± .020. Place washer (28) on screw

(40), apply green Loctite on threads and

place into shaft and tighten.

Figure 5

Service

Figure 6

PFG - HH & HV 2HP

Submersible Grinder Pumps

Figure 4

BACK TO INDEX