Powered by Safety

®

48

Maintenance

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

ii. If the circuit breaker did NOT

TRIP during the test performed

in

step 12

, reset the feeler gauges

with 0.030” selected and position

the feeler gauge as shown in

.

14. Slowly depress the trip coil armature

using the manual charge handle.

Position the handle as shown in

. Depress the handle until

the armature contacts the feeler

gauges. The circuit breaker should

trip.

Note:

Do NOT tilt the armature. Tilting the

armature by applying a load to the

right of the feeler gauges will produce

incorrect results.

15. If the circuit breaker did not TRIP

during the test performed in

step 14

, remove the feeler gauges

and trip the breaker. Decrease the

gap between the trip coil armature

and the trip lever by bending the

trip lever upwards slightly using

channel lock pliers or a small

crescent wrench. Repeat

steps 9, 10,

and 14

.

Note:

Bend the trip lever in very small

increments. This process may take

several attempts.

16. Repeat

steps 9 through 15

until

the breaker does not trip with the

0.090” gauge inserted in the trip coil

armature gap and does trip with the

0.030” gauge inserted into the trip

coil armature gap.

17. Manually CLOSE and TRIP the circuit

breaker so that all springs are

discharged.

18. Perform the latch check switch

adjustment per the procedure found

Ch 5 Maintenance, B. Mechanism

Area, 4) Slow Closing of Mechanism,

d. Latch Check Switch Adjustment

19. Replace circuit breaker front cover.

d. Latch Check Switch Adjustment

The latch check switch adjustment

) described is not required

for routine maintenance; however,

the latch check switch may need to be

adjusted after major overhaul, removal

of the mechanism, or tripping system

adjustment.

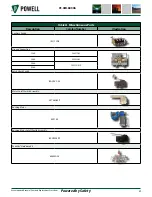

Figure 20 Latch Check Switch Adjustment

b

Pivot Screw

0.045"

a

c

d

a. Latch Check Switch

b. Latch Check Operator

c. Secondary Trip Prop Adjusting Screw

d. Secondary Trip Prop Adjusting Screw Nut

To adjust the latch check switch perform

the following steps:

1. Remove the main closing spring.

Refer to

B. Mechanism Area, 3) Closing Spring

2. Rotate the crank arms until the

spring charge indicator displays,

CLOSING SPRING CHARGED.