PONNDORF Gerätetechnik GmbH

Leipziger Strasse 374

D - 34123 Kassel

Operation Manual

Hose Pump Series

P_delta / PD-S

Page 18 of 29

Version 003_GB / 04.2021

6.3

Mechanical connection

The nominal width of the tubing at the suction and the discharge side

should be approx. 25 % bigger than the nominal width of the pump hose.

The size of the hose pump is concurrent to the width of the pump hose.

The tubing on the suction side must be vacuum proof (reinforced) and the tubing on the discharge

side must withstand the maximum pressure of the pump. By using a pole changing switch the tubing

on suction and discharge side must withstand the maximum pressure of the pump.

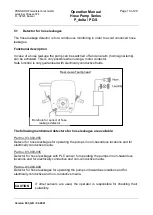

Always use flexible tubing to connect

the pump with the pipework of your application.

The length of the tubing should be

at least 1 m. (see fig. 6.3.1).

The standard way of connection is flexible tubing (fitting the connecting sockets of the

pump), fixed with hose band clamps. Other options (e.g. threaded connections, Kamlok

couplings, standard flanges) are available on request.

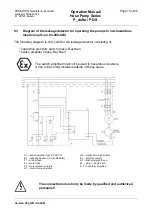

In order to avoid pressure peaks, which can cause damages of the pump hose, there

should no pipe bends or 90° elbows be installed directly after the pump on the discharge

side (please see fig. 6.3.2 and 6.3.3).

Furthermore the cross section of the pipework on the discharge side should not be reduced

(please see fig. 6.3.4).

CORRECT

Fig. 6.3.1

WRONG

WRONG

WRONG

Fig. 6.3.3

Fig. 6.3.2

Fig. 6.3.4

Summary of Contents for P delta 15

Page 1: ...Hose Pump Series P_delta PD S Operation Manual...

Page 2: ......