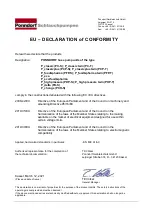

PONNDORF Gerätetechnik GmbH

Leipziger Strasse 374

D - 34123 Kassel

Operation Manual

Hose Pump Series

P_delta / PD-S

Page 23 of 29

Version 003_GB / 04.2021

7.2

Maintenance / Service

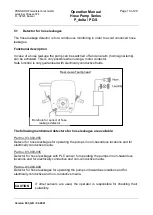

To guarantee a constant elasticity of the pump hose it must be lubricated with Ponndorf

Special Grease every 300 hours of operation. To do this remove the casing cover and put

some grease through the opening onto the running surface of the pump hose (e.g. by using

a screw driver).

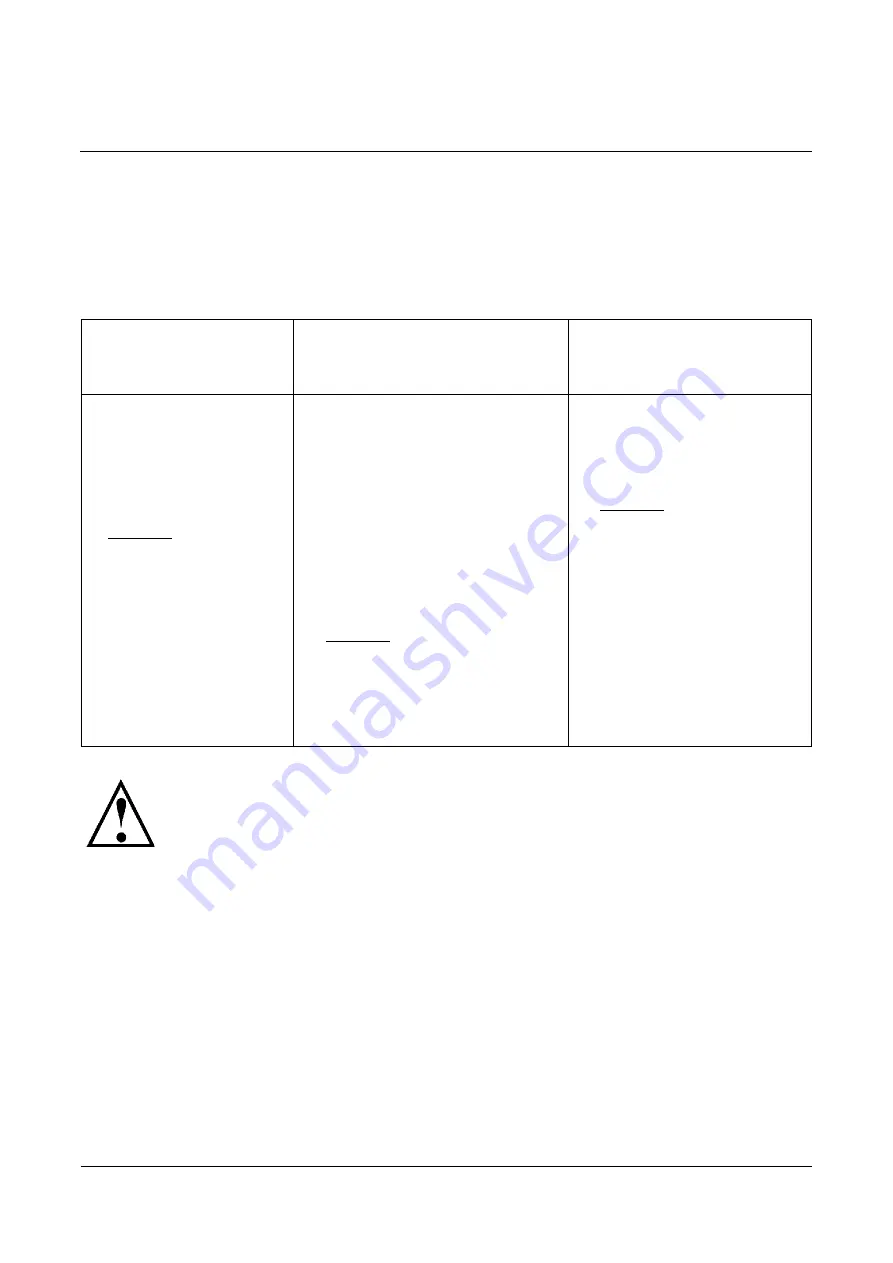

Outer surface of

the pump hose

Rotor bearings

Teflon rollers

• check on the grease

film (enough grease

on the running surface

of the hose?)

• Interval:

every 300 hours of

operation

• check on proper

seat of bearings

(no radial play!)

• check on unusual

heat generation

• check on unusual

and noticeable

bearing noises

• Interval:

every time when

changing the pump

hose respectively

every 500 hours of

operation

• check for proper seat (no

seized, not worn out)

• Interval:

every 500 hours of

operation

If the rotor bearings / Teflon rollers show the wear characteristics

mentioned above they need to be replaced.

7.3

Cleaning

After pumping media which tend to deposit, the pump hose must be rinsed out when

pumping is finished.

When changing the pump hose the inside of the pump casing should be cleaned properly.

Summary of Contents for P delta 15

Page 1: ...Hose Pump Series P_delta PD S Operation Manual...

Page 2: ......