Byte 3: Motor Number and Direction (continued).

"

Bit 7 must be cleared since this is not a start byte.

To obtain the complete byte 3 value from a motor number and a direction, multiply the

motor number by 2 and add 1 if the direction is forward. For example, to make motor 5

go forward, byte three should be 5

x

2 + 1 = 11. To make motor 1 go backward, byte 3

should be 1

x

2 = 2. (Two efficient ways to multiply by 2 in a microcontroller program

are shifting left by one digit or adding the motor number to itself.)

Byte 4: Motor Speed.

The most significant bit must be zero since this is not a start

byte, and the remaining seven bits are available for specifying the speed. The possible

range of values for byte 4 is thus 0x00 to 0x7F (0 to 127 decimal). 0x00 turns the motor

off, and 0x7F turns the motor fully on; intermediate values correspond to intermediate

speeds.

Resetting the Motor Controller

The motor controller’s optional reset line should normally be kept high at +5V. Pull the

reset line low to 0V for at least 2 microseconds to reset the motor controller to its initial

state (all motors off, waiting for the first serial command). You do not need to reset the

motor controller to use it successfully. However, you may need to reset the motor

controller to ensure that spurious signals sent when your robot controller turns on do

not cause the motor controller to detect the baud rate incorrectly.

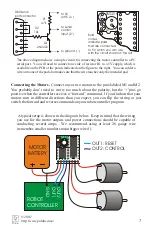

Controlling Multiple Motor Controllers with One Serial Line

To control a particular motor, you must specify its motor number in command byte 3.

For all motor controller boards, motor M1 responds to commands for motor number 0,

and M2 responds to commands for motor number 1. To control more than two motors

with a single serial line, you need to use motor numbers 2 through 63. Motor

controllers that are not specially ordered respond to numbers 2 and 3; you need to order

specially programmed motor controllers to use motor numbers 4 through 63.

For example, to control six motors independently, you need three motor controller

boards, each with different motor numbers. All three motor controllers respond to

commands for motor numbers 0 and 1. For controlling the six motors independently,

use motor numbers 2, 3, 4, 5, 6, and 7. (The exact numbers depend on which motor

numbers you request when you specially order additional motor controllers.)

You can individually control up to 62 motors at a time with a single serial line using 31

motor controllers: one with the default program and 30 that are specially programmed.

9

Pololu

© 2001

http://www.pololu.com/