Example BASIC Stamp II Program

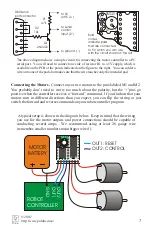

This program, which can run on a BASIC Stamp II controller, makes motor 1 gradually

speed up, then slow down, then speed up in the other direction, and then slow down

again. For the code to work, pin 15 must be connected to the reset input (‘1’), and pin

14 must be connected to the serial input (‘2’). The interface code should look similar in

other programming languages; the description below should help you in understanding

the code and, if necessary, in translating it to other languages.

On line 1, the 8-bit variable

speed

is declared for later use. The motor controller is

then reset by a low-going pulse on pin 15 (lines 2 and 3).

The first

for loop

on lines 4-7 causes motor 1 to gradually speed up. The serial output is

created by the

serout

statement on line 5. The first parameter, 14, specifies the pin

number through which to send the serial signal. The next parameter,

32

, sets up the

serial characteristics to be 8 bits with no parity, non-inverted, at a baud rate of 19200.

The four numbers in square brackets are the data to be sent, and they correspond to the

four control bytes for the motor controller. The first two bytes should always be

$80

and

0

. The second

0

makes motor 1 go backward. The speed variable, which increases

every time through the loop, is the only part of the command that changes, and that is

what makes the motor gradually speed up. The

pause

statement on line 6 causes the

program to wait for 20 ms (0.02 seconds) before sending the next command.

When the first loop ends, the motor is set to its full speed of 127. The second loop on

lines 8-11 slows the motor back down by sending speeds from 127 down to 0. The next

two loops on lines12-19 then repeat the process, except for the parameter value of

1

in

byte three, which causes motor 1 to spin forward.

1

speed

var

byte

2

low 15

'reset motor controller

3

high 15

4

for speed = 0 to 127

5

serout 14,32,[$80, 0, 0,speed]

6

pause 20

7

next

8

for speed = 127 to 0

9

serout 14,32,[$80, 0, 0,speed]

10

pause 20

11

next

12

for speed = 0 to 127

13

serout 14,32,[$80, 0, 1,speed]

14

pause 20

15

next

16

for speed = 127 to 0

17

serout 14,32,[$80, 0, 1,speed]

18

pause 20

19

next

10

Pololu

© 2001

http://www.pololu.com/