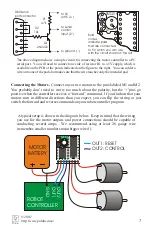

How the Motor Controller Works

The motor controller uses

H-bridges

to turn motors forward and backward (see the

dotted ‘H’ in the left figure). H-bridges have four switches, which are turned on in pairs

to allow current to flow into the motors in both directions, as shown below. In the left

figure, all four switches are open, and the motor is turned off. When switches 1 and 4

close, the motor turns in one direction; when switches 2 and 3 close, the motor turns the

other way. Integrated circuit U2 contains two H-bridges, allowing bidirectional

control of two motors.

A technique called

pulse width modulation

(PWM) is used to control the speed of the

motors. The microcontroller (U1) is a little computer that controls the H-bridge

switches. It turns the switches on and off very rapidly (600 times per second) and

varies the percentage of the time that the switches are on to achieve the speed set by the

serial interface. For a higher speed, the switches are on a larger fraction of the time than

for a slower speed. At the maximum speed of 127, the switches are left on. The

momentum of the motor shaft keeps the shaft spinning at a constant speed that can be

varied smoothly over all 127 different speeds.

U3 and the capacitors provide a steady 5V power supply for the microcontroller, which

cannot run at the full motor voltage provided to the board at the ‘+’ and ‘

-

’ pins.

The complete schematic diagram of the motor controller is shown below:

11

Pololu

VIN

VOUT

GND

LM2931

U3

SN754410

1,2EN

1Y

1A

GND

GND

2A

2Y

VMOT

VCC

3Y

4A

GND

GND

3A

4Y

3,4EN

4

5

12

13

2

7

10

15

1

8

9

16

3

6

11

14

U2

PIC12C508A

GP2

VSS

VCC

GP0

GP1

GP4

MCLR

GP5

4

3

8

1

5

7

2

6

U1

C1

100

C2

22

+

2

-

1

+

-

+

-

M1

M2

M

V+

V-

M

V+

V-

M

V+

V-

1

2

4

3

1

2

4

3

1

2

4

3

© 2001

http://www.pololu.com/