Next, solder in your choice of connector. You can use

either the straight or the right-angle female header

provided in your kit, or use your own connector. If you

prefer having leads soldered directly to the PCB, you

can do so now or wait until you have the leads ready and

available.

6

SMC01A

C

2

C

1

U3

U2

U1

M2

1 2

M1

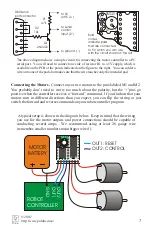

Finally, insert the two integrated circuits (ICs), U1

and U2, into their sockets.

Make sure that you plug

them in so that the notches on the ICs match the

notches on the PCB outline. Do not solder the ICs

to the sockets.

If you soldered the sockets in

backwards, it doesn’t matter as long as the actual

component is oriented correctly.

Be careful: the ICs

are static-sensitive

, so take appropriate precautions

and avoid touching their leads. You may need to bend

some of the leads to make them fit in the sockets; if so,

hold the plastic body of the IC and push the pins

(gently!) against a flat surface, one row at a time.

7

SMC01A

C

2

C

1

U3

U2

U1

M2

1 2

M1

5

Pololu

SMC01A

C

2

C

1

U3

U2

U1

M2

1 2

M1

Next, add the tantalum capacitor C2. You may need to

bend the leads to make them straight so that they will

fit. The capacitor is

polarized

, which means it

must

only go in one way

. Make sure the side labeled with a

“+” and a stripe goes into the hole that is also marked

with a “+”. If the PCB is oriented as shown in the

diagram, the lower hole is for the positive lead.

3

+

SMC01A

C

2

C

1

U3

U2

U1

M2

1 2

M1

Now, add the voltage regulator, U3. Make sure the

device is oriented as shown on the silkscreen drawing,

with the flat side facing the outside of the PCB.

Caution! The voltage regulator can be damaged by

static electricity.

4

SMC01A

C

2

C

1

U3

U2

U1

M2

1 2

M1

In this step, add your choice of electrolytic capacitor for

C1. The larger capacitor is necessary if you want to run

your motors off of a 24-volt power source, and you

should use it if you don’t care about the size of the

completed motor controller.

The electrolytic

capacitors are polarized, but this time the stripe

identifies the negative terminal.

Also, the positive

lead is longer. Make sure to match up the positive lead

with the appropriate hole in the PCB.

5

+

+

© 2001

http://www.pololu.com/