SprintScan 35LE Service Manual

Troubleshooting

27

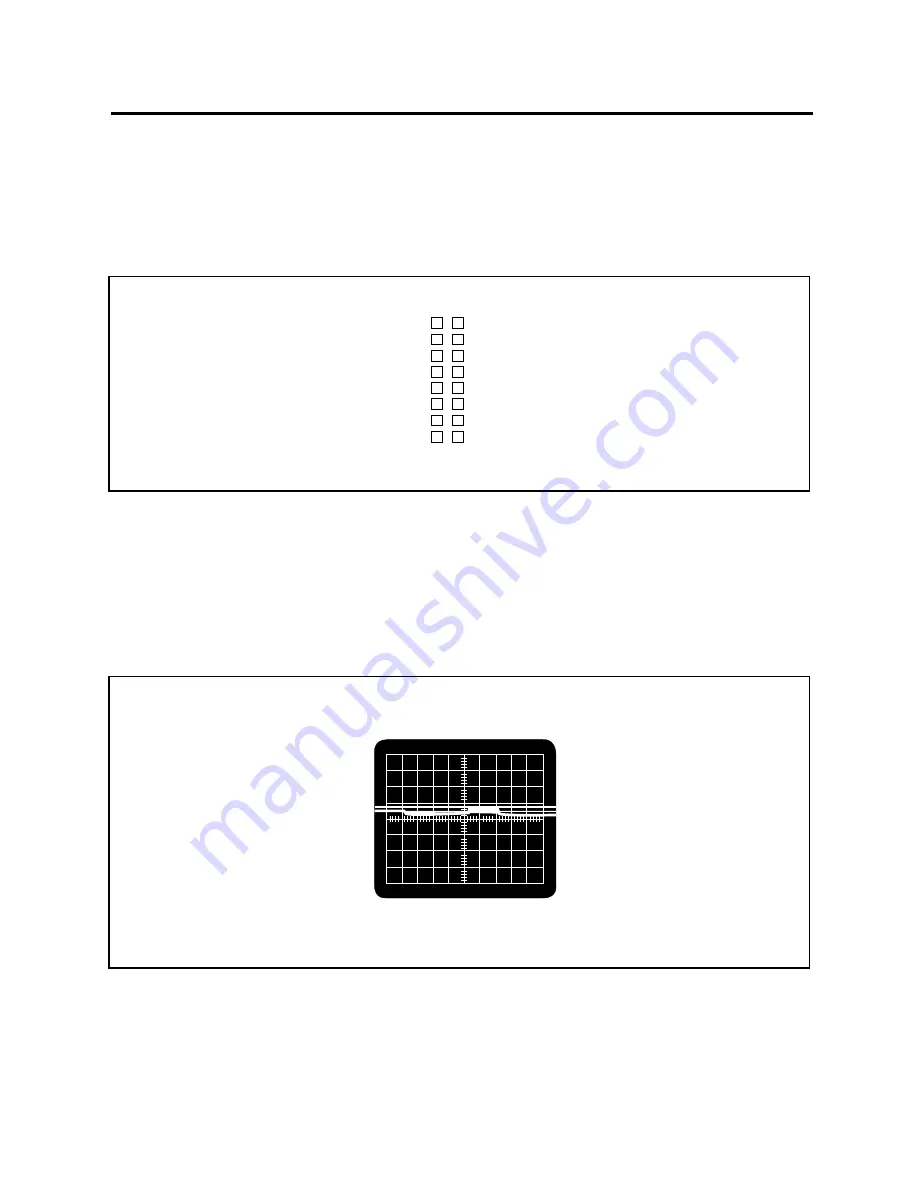

1. Unplug connector J7 and check the CCD module output signals. Figure 3-4 shows

the pin designations for connector J7.

Note: The signals that drive the CCD module are outputted at connector J7 on the

main PC board.

Figure 3-4. Pin assignment for connector J7

2. Check the CCD output signal at J7, Pin 16. Figure 3-5 shows the correct output

waveform.

Note: If the output waveform is incorrect, replace the CCD module.

Figure 3-5. Preprocessing CCD Output Waveform at J7, Pin 16

OS

AGND

+12V

PHIR~

PHI1A~

DGND

PHI2A~

DOS

AGND

DGND

DGND

DGND

PHIX~

+12V

1

3

5

7

9

11

13

15

2

4

6

8

10

12

14

16