7

Installation

Installation

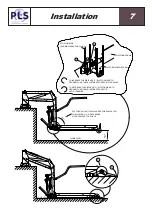

Fitting sequence

Please refer to the following pages for accompanying installation diagrams.

When positioning the lift into the vehicle:

1. Roll off ramp (wheels) must be clear of rear doors, minimum 15mm.

2.

When the lift is powered “down” t

he bridge plate mechanism must be clear

of the rear bumper or side valence.

3. The distance between the inside of the door aperture and the outside

of the handrails should be equal both sides.

4. All manual override systems must be fully accessible.

5. The vehicle surface MUST be flat. Do not attempt to mount base plate on top of seat

tracking extruded sections. Shim base plate above tracking if necessary.

If the surface is not flat, when the lift is bolted down the base could distort to the

contours of the floor. This will have the effect of altering the position of the lifting arms,

thus twisting the lift.

THIS WILL AFFECT PRODUCT WARRANTY.

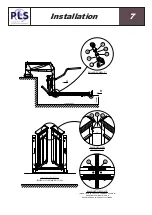

When bolting in the base:

1. PLS universal fitting plates should be used instead of washers!

2. At least two of the front bolts (closest to driver) should be located through the

vehicles chassis.

NB. WHEN FITTING EAB A “FULL” REAR BEAM MOUNTING BRACKET SHOULD

BE USED.

Adjusting lift:

1. Ensure vertical stow position is set correctly.

2. Ensure horizontal platform position is set correctly.

3. Ensure roll-off ramp end of platform lands on ground first.

4. Ensure platform is symmetrical (not twisted)

5. Ensure Platform gates are locating together correctly.

6. To correctly adjust the Platform Knuckles

see Platf

orm Gates “Synchronizing”

Procedure in section 7.4

To Finish:- Weight Test Lift to current LOLER recommendation/ regulations.

1. Check all fitting bolts are tightened to correct torque setting.

2. Check all lift fastenings are tight.

3. Ensure all information decals are positioned correctly.

4. Lift serial number and SWL are visible.

5. Fill in weight certificate.

6. Fill in LOLER certificate.

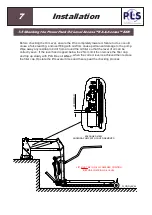

7:2 General Installation Access™ EA & Access™ EAB

1.01

4.01

.0

3.02

2.15

2.19

2.21

3.04

7

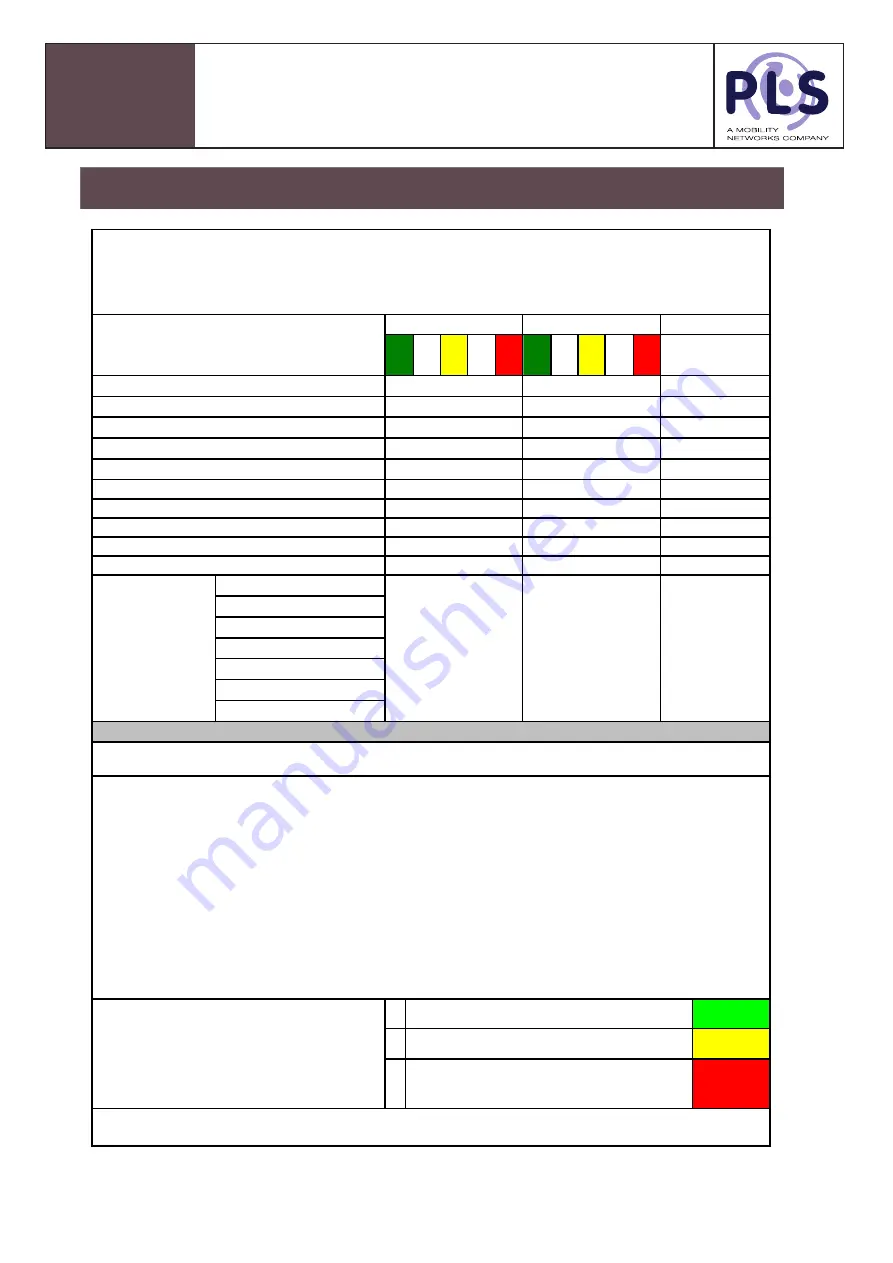

7.1 General Installation- Risk Assessement Access™ EA & Access™ EAB

Installation

7

Location: Passenger Lift Services Ltd

Rev No:

Operation/Activity: Lift Operation

List below the operations, in your

Severity

Likelihood

Risk Rating

opinion, which involve a significant

1 2 3

4 5

1

2 3

4 5

= S x L

hazard, risk of injury?

Stability of lift during operation

2

1

2

Entrapment from moving parts

2

1

2

Slips, trips and falls

3

1

3

Operating environment

3

2

6

Manual operation of lift

2

1

2

Contact with hazardous substances

2

1

2

Fire

1

1

1

No injury just minor damage to

plant, equipment or structure

List persons at

Operators

Minor injury – small cut or bruise

Rare - may occur only in

exceptional circumstances. (0-

20% chance)

18

Serious – medical treatment

required – doctor or small injury

Moderate - could occur at

Overall risk

clinic

sometime. (41-60% chance)

rating

Major – attendance at hospital

Likely - not surprised could occur

accident and emergency

several times. (61-80% chance)

department

Certain - to be expected, will

Fatalities

occur repeatedly. (81-100%

chance)

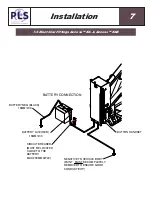

Risk rating has been defined taking into account the following control measures

Control measures include (engineering quality control, specialist equipment information / instruction, Customer

responsibilities maintained.

Action Plan / Controls:-

All lifts are supplied with safety instructions and safe operating procedures with visual instruction

for the automatic and manual operation of lifts.

Safety instruction is also generated and supplied for the use of lifts by scooters and large powered

wheelchairs.

Supply and fitted lifts have a weight test certificate and an installation and examination report

completed by a competent engineer complying to; Lifting Operations and Lifting Equipment

Regulations 1998.

Additional controls are to be implemented and maintained by the end user, with six monthly

inspections carried out on all lifting equipment conforming to; Lifting Operations and Lifting

Equipment Regulations 1998.

Has the overall risk rating been reduced to Low?

Controls are deemed adequate- proceed with the

1-7

operation/activity

Has the overall risk rating been reduced to

X

Consider additional controls, strict monitoring of

8-20

controls required -proceed with caution

Medium?

Operation / activity is NOT to be undertaken until

21-30

Has the overall risk rating remained High?

additional controls have been implemented - contact

safety officer

Can the risk be reduced to low by introducing additional preventative and/or protective measures? No

See Risk Assessment Action Plan for additional precautions / controls to be implemented.

Assessment carried out by:

Position:

Date:

REMEMBER: REVIEW THE ASSESMENT IF THE CIRCUMSTANCES CHANGE SIGNIFICANTLY

7.1 General Installation- Risk Assessment Access™ EA &

Access™ EAB