10

Service &

Maintenance

Weekly Inspection Check List

Lift no:

Vehicle Reg:

Engineer’s Name:

Date:

Customer Details:

Address, Contact:

Tel Number:

OK

1 Visually check fluid level.

2 Visually check for any leaks or damage.

3 Check for obvious signs of damage, and notify as manager if necessary.

4 Ensure that the Operation instructions are visible.

5 Ensure the hand Pump Handle is present.

6 Ensure the Handset control is working correctly and there are no signs

of damage.

7 Ensure the Platform Hinges are clean/ dry and correctly lubricated using

ACF-50 spray.

8 Ensure the Platform Knuckles are clean/ dry and correctly lubricated

using ACF-50 spray.

9 Ensure the Platform Pivots are clean/ dry and correctly lubricated using

Lithium Grease EP2.

10 Ensure the Stow Linkages (Upper & Lower) are clean/ dry and correctly

lubricated using ACF-50 spray.

11 Ensure the Handrails are clean, working correctly and rust free.

12 Ensure the Handrail mechanisms are working correctly & lubricated

using ACF-50 spray.

13 Ensure the Arm guards are present and undamaged.

14 Ensure the Bridge Plate Hinge is working correctly & lubricated using

ACF-50 spray.

15 Ensure the Roll-Off-Ramps are working correctly & lubricated using

ACF-50 spray.

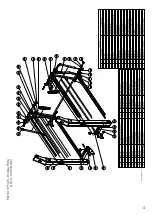

10.4 Weekly Inspections Access™ EA & Access™ EAB

Service &

Maintenance

IF IN DOUBT, CONTACT THE MANUFACTURER

Lift Inspection checks are required on a WEEKLY basis by the lift operating company.

The working life of your lift will be greatly prolonged if these steps are adhered to.

This should include the following:

10

Monthly Inspection Check List

Lift no:

Vehicle Reg:

Engineer’s Name:

Date:

Customer Details:

Address, Contact:

Tel Number:

OK

1 Check for obvious signs of damage and replace defective parts where

necessary.

2 Check the operation and stowing of the lift.

3 Check rear Roll-Off Ramp operation and lubricate as necessary.

4 Check Platform alignment (pin location), adjust Platform Knuckles as

necessary.

5 Ensure the Handset control is working correctly and there are no signs of

damage.

6

Check lift ‘vertical’ stowing position. Lift should be clear of rear doors and

only lower when the down button is depressed

7 Check P

latform ‘horizontal’ position. Each side

of the lift platform can be

adjusted independently if required.

8

Check Power Pack oil reservoir (when the lift platform is completely

stowed) if necessary, top up slowly with PLS Blue oil ONLY to within

25mm from

“max”

level.

9

When cleaning the vehicle, wash the working platform of the lift. For best

results use a stiff brush and soapy water. Replace any missing 3M

surface tape as necessary.

10 Lubricate all required parts.

11 Check the condition/ correct operation of the Platform Knuckles.

12 Ensure the Bridge plate and linkages are working correctly

.

10.5 Monthly Inspections Access™ EA & Access™ EAB

Service &

Maintenance

IF IN DOUBT, CONTACT THE MANUFACTURER

Regular lift maintenance is recommended at MONTHLY intervals by the lift

operating company. The working life of your lift will be greatly prolonged if these

steps are adhered to.

10

10.4 Weekly Inspections Access™ EA & Access™ EAB