8

MT 237 – EN ed.2015 (Rev.A)

2.2

CONNECTING THE EQUIPMENT

The valve has to be installed on the line with the arrow on the body positioned in the gas flow direction.

The connections between the equipment and the piping have to be carried out using a stainless steel or copper pipe, having a minimum

internal diameter of 8 mm.

To obtain the correct operation, it is essential that the downstream sensing line is connected to a straight section of the piping itself,

having a length equal to 4 times the piping diameter (therefore, without any possible signal turbulence), as well as that the maximum gas

speed at the sensing point does not exceed 30 m/sec.

In order to prevent impurities and condensation to deposit in the pressure sensing tubes, it is advisable to provide for the following:

the tubes shall always be positioned on a descending slope towards the connection of the outlet piping with a slope of about 5 -

10%;

tube branch connections shall always be welded on the upper part of the piping itself and the hole on the piping shall not show

any burrs or projections towards the internal side.

To avoid breakages or unwanted deformations, it is recommended to provide for the following:

the equipment shall be installed pursuant to the regulations in force and the good practice

that shall not be any external loads acting on the device

the equipment shall be provided with adequate protection and grounding means to protect it against stray currents and

electrostatic potential differentials

the equipment shall be used within the limits set on the rating plate

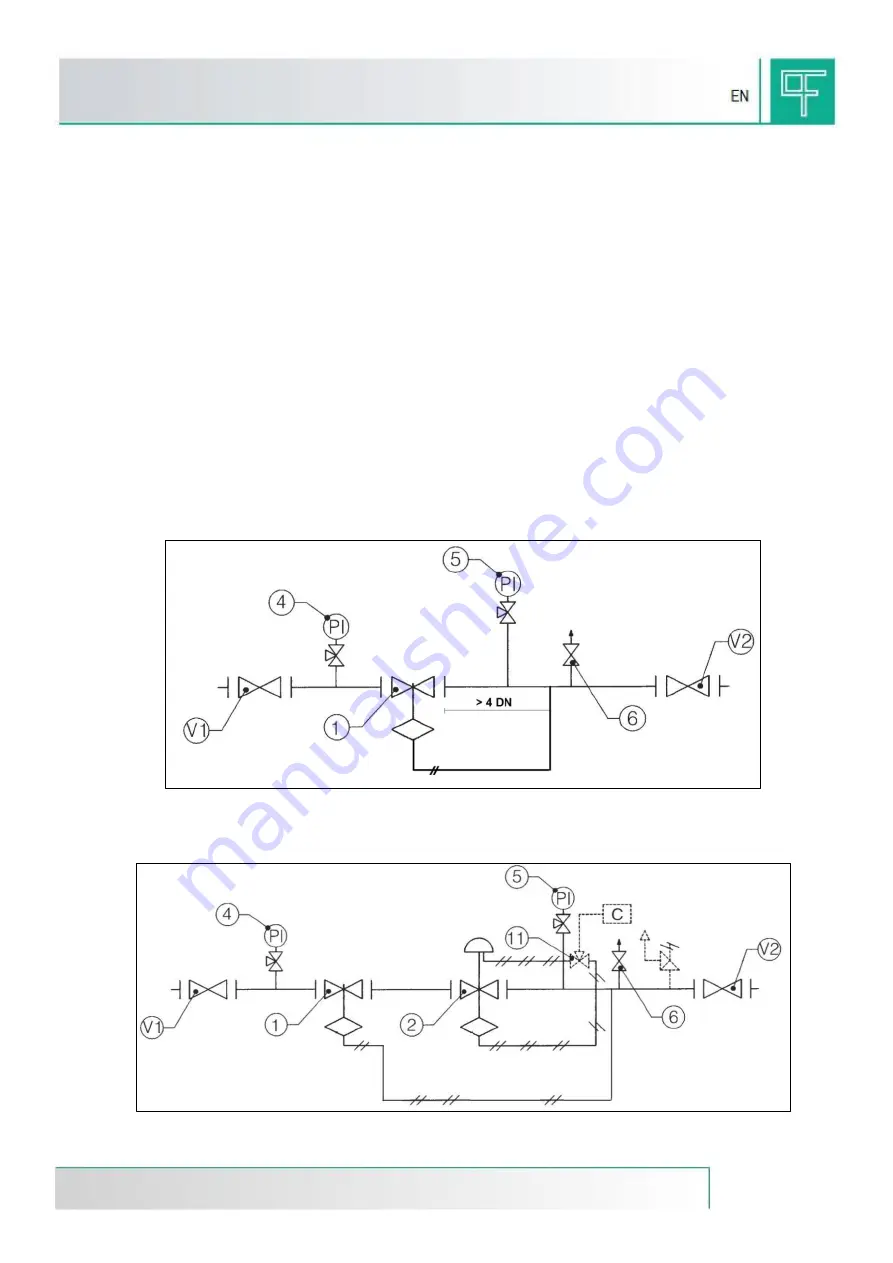

The most frequent types of installation on a gas pressure reduction line of the valve DILOCK are shown in the figures 4 and 5.

Installation of the valve on a piping segment

Figure 4: Installation diagram

Installation of the valve on a gas pressure reduction line as safety in case of fault of the pressure regulator

Figure 5: Installation diagram

Slam-shut

valve

Sensing line

Pressure gauge

Relief valve

On-off valve

Pressure gauge

On-off valve