7

8

1.

Go to support on www.photocentricgroup.

com and select LC Pro. Click on ‘Downloads’

and download the latest version of Creation

Workshop.

2. Make sure the DisplayPort, USB and power

cables are plugged into the printer and then

turn on the power using the rocker switch at the

back. Turn on the screen using the switch at the

front of the printer.

3. Go to your computer desktop, right click and

open “Display Settings”. Set your screens to

“Multiple Displays” and “Extend this display

mode”, keeping your computer monitor as the

main screen. Make sure that the printer’s screen

is set to a resolution of 3840 x 2160. There are

videos online if you need further help. If Creation

Workshop or Photocentric Studio software

doesn’t recognise 4k resolution and only 2k the

carry out the following;

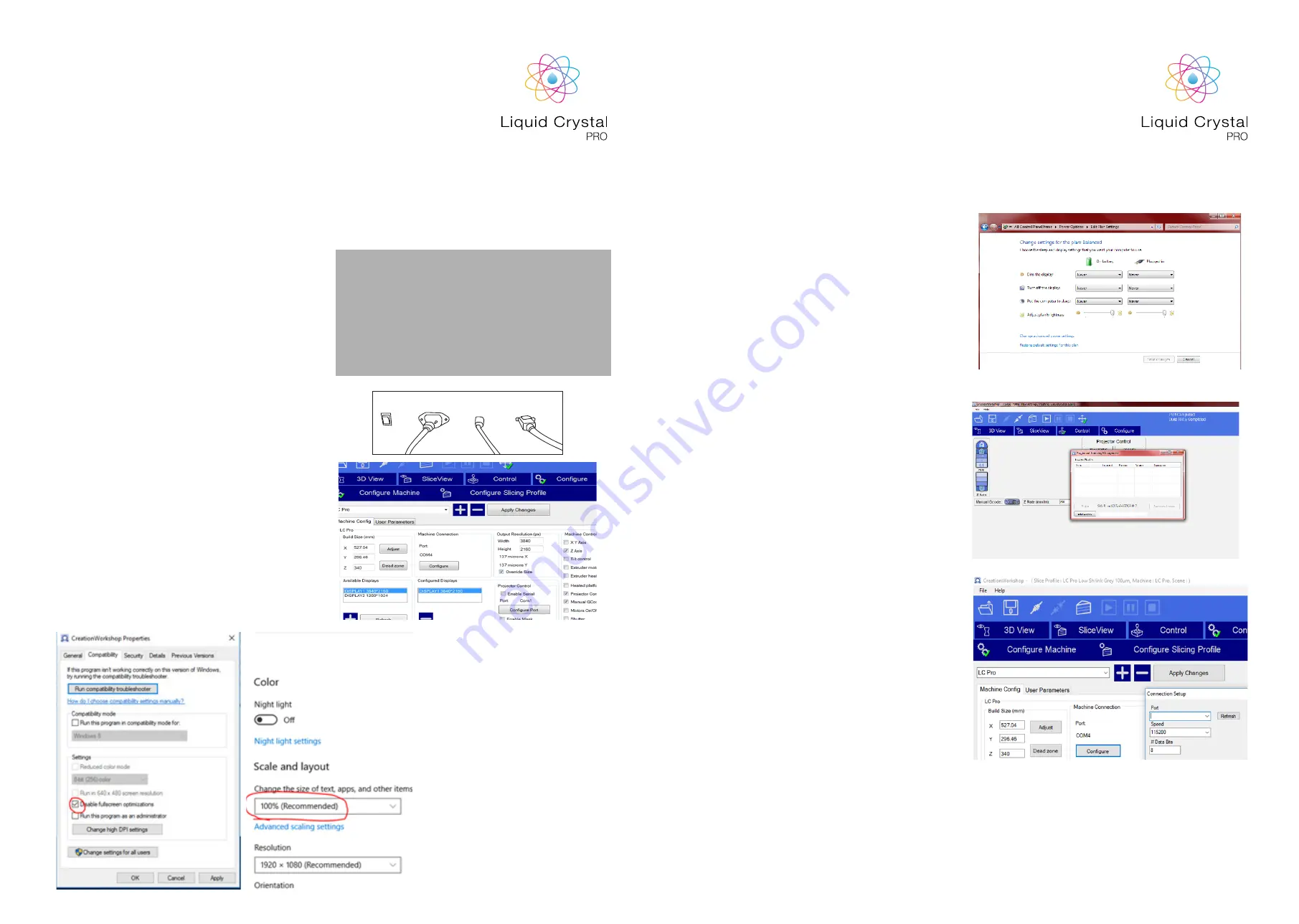

On Windows 8, right click on software shortcut,

Properties then Click on ‘Disable fullscreen

optimization’. Refer bottom left screenshot on

page 7.

On Windows 10 go to windows display settings,

choose printer screen, change scale and

layout from 200% to 100% Refer bottom right

screenshot on page 7.

When this is complete reboot the software.

1.1. SOFTWARE

INSTALLATION CW

MINIMUM COMPUTER

REQUIREMENTS

• Dual Core processor or above

• Windows

• Software NOT compatible with MAC and

Linux

• 2 GB RAM memory or above

4. Configure your computer so that the screen-

saver does not come on and ensure that it does

not have the power-saving mode enabled. If you

forget to do this your computer may shut down

mid process and the printer will switch off.

Note:

You will need to connect to the internet

within 30 days of using your Creation Workshop

license otherwise the license will deactivate. The

license number can be found on the back of the

printer. Then going forward the codes will need to

be recognized online every 30 days after the first

activation to validate and update the software.

5. Execute the Creation Workshop software by

double clicking on “CreationWorkshop.exe”. If

the software requires a license number insert

the license number supplied on the back of the

printer.

6. In Creation Workshop, click on “Configure”, and

then open the subfolder “Configure Machine”. In

the configuration folder connect the printer to the

computer by clicking on the button “Configure”

in the Machine Connection section. Select the

port you have connected the USB to and set the

speed to 115200 and data bits to 8. Press “OK”

and finally press “Apply Changes”. Now click

[CONNECT ICON] to connect your computer and

the Liquid Crystal. If there is a USB driver error

you can download the driver from the below web

addess;

https://photocentricgroup.com/lcpro-support/

7. If you are experiencing difficulties to start or

connect your printer, go to our website www.

photocentricgroup.com, and visit “Support”.

You will find videos that will run you through the

issues you may find due to specific computer

settings. Should you still find difficulties, please

contact your national supplier or contact us at

[email protected].