4. REMOVING THE

FINISHED PART,

CLEANING AND

POST-EXPOSING

17

18

1

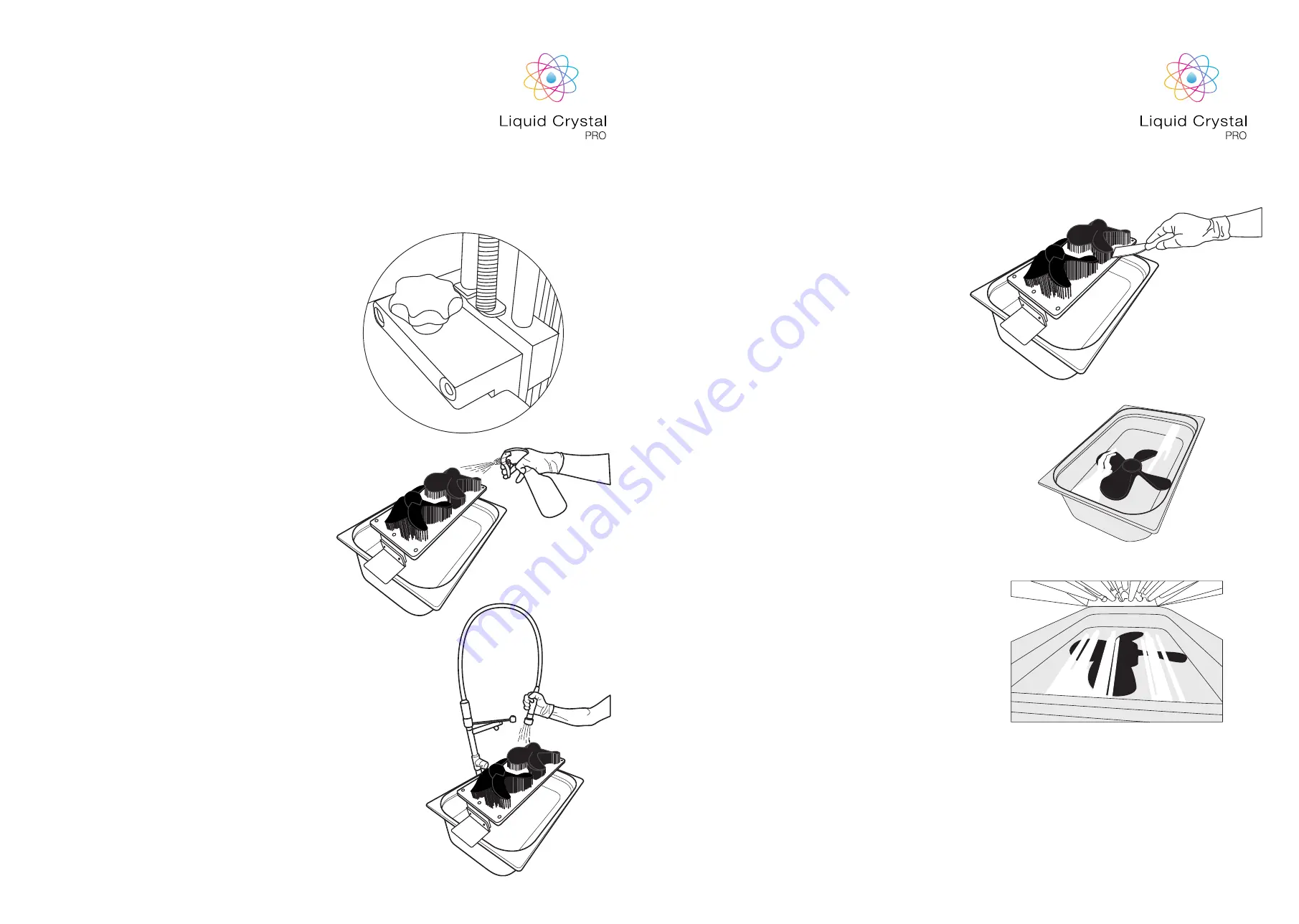

. Use your print controller to drive the print plate

up until the print is clear of the vat. Allow the

print to drain for a few minutes to reduce the

chance of drips.

2. Make preparations for cleaning the print. You

will ideally need a large sink with a good supply

of hot water. The ambient light level should be

low. Have a spray bottle with a hot, very dilute

solution of washing up liquid is also useful.

Wear protective gloves at all times you come

into contact with liquids. You can also clean

with IPA if available (Iso Propyl Alcohol).

3. Loosen the bolts that secure the print plate

to the drive carriages. Grip the print plate L

brackets firmly and take the weight of the print.

Carefully slide the print plate towards you and

out of the machine. Close the printer door take

care not to drip resin.

4. When your print is finished remove the platform

from the printer and lay it with the object

facing upwards in a large plastic tray. Spay the

part throughouly to remove all the unreacted

surface polymer. When you have covered the

entire surface, finish by spraying with warm

water. You can use a sponge or soft brush to

clean detailed parts. Alternatively use a large

utrasonic cleaner.

5. Using a scraper detach the supports at the base

to remove the part from the platform. Handle it

gently as it won’t achieve full strength until after

full post exposure. Note that for large models,

we recommend post curing the model on the

build plate in order to minimize any possible

warping. If your part is strongly adhered to the

build platform you can aide removal by heating

the metal to expand it by applying hot water or

a hot air gun to it.

6

. Fill the tray with clean water and place the

part in it so that it is fully covered. Expose to

strong visible or UV light for 120 mins to dry the

surface and achieve full hardness. In the case

of larger prints you will have to turn it over so

the underside receives light as well. For larger

models, we recommend placing the whole

platform in water under UV light.

7. Clean the print plate thoroughly. Make sure all

cured resin is removed from the underside of

the plate as this may cause damage to the vat

or screen. Hot soapy water and/or methylated

spirits can be used to clean off uncured resin.

Make sure the print plate is completely dry

before returning it to the printer.

8. Once the printed part(s) have been fully post-

exposed they should be removed from the

water and dried thoroughly. Any support

material can be removed using clippers.The

part can be sanded if neccessary.