OPUS

Liquid Crystal

OPUS

Liquid Crystal

5. Please refer to the selected Photocentric Resin

Cleaners’ TDS for guidelines on wash cycle time and

subsequent steps.

- Photocentric Resin Cleaner TDS

- Photocentric Resin Cleaner 30 TDS

Parts can be cleaned in 15 minutes using Photocentric

Resin Cleaner or alternatively, in 10 minutes using

Photocentric Resin Cleaner 30.

6. Once the print has been washed, rinse using water

to remove excess resin and solvent. For Photocentric

Resin Cleaner, rinse using hot water. For Photocentric

Resin Cleaner 30, rinse using warm water.

7.Photocentric highly recommends using

compressed air to dry parts thoroughly.

Alternatively, leave rinsed parts aside to dry.

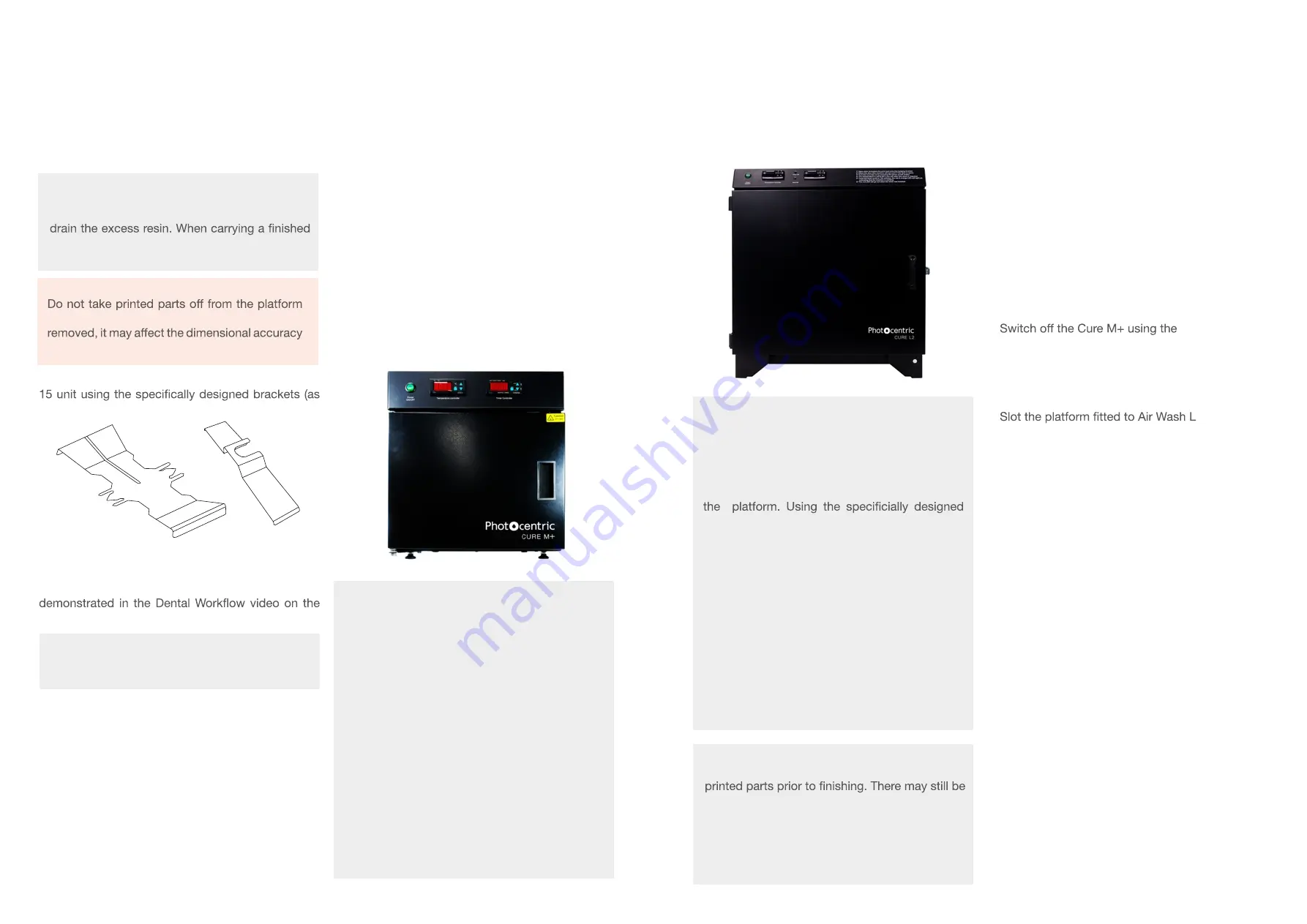

Cure M+

1. Switch on the Cure M+ using the

power switch at the front.

2. Place platform on the base of the cure

unit and close the door, securing with the

safety latch on the right-hand side.

3. Set the timer for 60 minutes at 60°C

or until parts are fully cured.

4. Remove the platform from Cure M+. Please

refer to Section 8.1 for further guidance

on removing parts from the platform.

5.

power switch at the front.

Cure L2

1.Switch on the Cure L2 using the

power switch at the front.

2.

bracket into the Cure L2 with parts facing

down, securing the handles on the inserts.

3. Set the timer for 60 minutes at 60°C

or until parts are fully cured.

4. Remove the platform and the bracket from the

Cure L2. Please refer to section 8.1 for further

guidance on removing parts from the platform.

8.1 REMOVING PARTS FROM

THE PRINT PLATFORM

To remove parts from the print platform, Photocentric

recommend thermal shocking (with the exception of

Durable UV80 resin).

1. Upon removing platforms from the cure unit,

submerge fully in cold water.

2. Parts will become immediately free from the

platform.

Alternatively, parts can be removed from the

platform using the scraper or cutters provided in the

Accessory Box.

Cut through the supports to free parts.

All parts produced using LC Opus will need to be

post-cured using UV light and heat to fully cure the

resin and achieve the correct material properties.

Photocentric recommends using the Photocentric

Cure M+ and Cure L2

8. POST-CURING

Cure M+

External dimensions are:

440 (W) x 270 (D) 390 (H) mm.

Internal dimensions are:

350 (W) x 270 (D) x 260 (H) mm.

You can cure parts with 160mm height on the

platform.

Photocentric Cure M+ can be purchased from

this

webpage

The user manual for Cure M+ can be downloaded

from this

webpage

. Or from

LC Opus Resource

Hub.

Here, you can also browse guidance on the

following:

- Using your cure unit

- Programs

- Maintenance

- Environmental Operating Conditions

Cure L2

External dimensions are:

700 (W) x 600 (D) x 700 (H) mm.

Internal dimensions are:

500 (W) x 350 (D) x 550 (H) mm.

You can cure parts with 220mm height on

Air Wash L bracket, one or two Opus

platform(s) can be post-cured simultaneously.

Photocentric Cure L2 can be purchased from

this

webpage.

The user manual for Cure L2 can be downloaded

from this

webpage

, Or from

LC Opus Resource

Hub.

Here, you can also browse guidance on the

following:

- Using your cure unit

- Programs

- Maintenance

- Environmental Operating Conditions

Photocentric Cure M+

Photocentric Cure L2

NOTE:

Wear gloves when handling platforms with

traces of liquid resin or cleaning product on the

surface. Handle the parts with care.

NOTE:

Wear heat resistant gloves when handling

platforms after curing.

14

13

3.Grip the handles of the print platform securely and

gently pull towards you to remove it.

4. Place the platform into either Air Wash L or Wash

shown below).

When using Wash 15, ensure the basket is removed

prior to parts being washed. This has been

LC Opus Resource Hub.

Air Wash L Bracket

Wash 15 Bracket

NOTE:

Wear gloves and safety glasses when working

with Photocentric Resin Cleaners.

NOTE:

After removing the print platform from the printer,

it can be helpful to tilt it and hold it over the vat to

print to your cleaning station, use paper towel or

a suitable tray to catch any drips.

WARNING

prior to the Cleaning and Post-Curing steps. If

of parts.