RECOMMENDED

ADDITIONAL ITEMS

Safety Glasses

Paper Towel

Spray Bottle

Sink

Cleaning Solvent

(e.g. Isopropyl Alcohol)

Resin*

Photocentric LC Opus

Wash 15*

Photocentric LC Opus

Air Wash L*

Photocentric Cure M+*

Photocentric Cure L2*

Liquid Crystal Opus

Vat Film Pack*

Liquid Crystal Opus Resin Vat*

Liquid Crystal Opus

Print Platform*

* Available from Photocentric

This information must be read through carefully

for Liquid Crystal Opus User Safety. Retain this

information for any future reference.

- Follow all instructions displayed on the 3D printer.

- Liquid Crystal Opus weighs 38kg. Two people are

required to lift it safely.

that can safely support the weight.

- Position the 3D printer at a height that allows a

comfortable posture during operation.

- Keep the 3D printer and photopolymer resin out

of the reach of children.

- Liquid Crystal Opus requires a mains power

supply with a voltage of 110-230VAC and a

frequency of 50-60Hz.

- The main power consumption is 500W. It will draw

a maximum of 3A when connected to 230VAC, or

5A when connected to a 110VAC.

- Only connect Liquid Crystal Opus to the mains

socket using the power cable supplied.

- Ensure that the total current draw of all items

connected to the mains circuit does not exceed

the capacity of the fuse or circuit breaker.

- Always plug the power cable into the mains

socket and the 3D printer before switching on the

power at the back of the 3D printer.

printer before unplugging the power cable from

either the 3D printer or the mains socket.

- Do not place anything on top of, or resting against,

the power cable.

- Do not open the printer hood whilst working parts

are moving, they present a crushing hazard.

- Do not position the power cable that it causes a

trip hazard or is likely to be stepped on.

- Disconnect the 3D printer from the mains socket

when not in use.

- Do not operate Liquid Crystal Opus outdoors.

- Liquid Crystal Opus should not be operated in

direct light from the sun or any UV light source.

ambient light for long hours.

- Liquid Crystal Opus should be operated in an

ambient temperature of 20°C-25°C.

- Liquid Crystal Opus should be operated in a well-

ventilated room.

- Do not operate Liquid Crystal Opus with the hood

open as you may be exposed to crush hazards,

harmful UV light or other hazards.

- Photopolymer resin is an irritant. Always wear

gloves and safety glasses when handling.

- Do not operate Liquid Crystal Opus if you display

signs of sensitivity after exposure to photopolymer

resin, such as skin or eye irritation.

- Do not allow photopolymer resin or any other

liquid to get inside the casing of the 3D printer.

Clean up any spills immediately.

the mains socket and disconnect the 3D printer

immediately.

- Do not disassemble Liquid Crystal Opus as

you may be exposed to electric shock hazards,

harmful UV light or other hazards.

- All repairs should be carried out either by or with

the assistance of Trained Personnel.

- Discontinue 3D printer operation and contact

your supplier if:

The power cable or plug is damaged.

Liquid has got inside the casing of the 3D

printer.

The 3D printer has been dropped.

The 3D printer shows signs of damage.

The 3D printer does not operate correctly

after following the instructions provided in

this user manual.

- Dispose of waste photopolymer resin according

to the SDS of the material and in line with local/

national regulations. Do not dispose of this

through typical plumbing systems.

- Dispose of Liquid Crystal Opus responsibly. Please

recycle where possible or return to Photocentric

for recycling.

3. SAFETY

INFORMATION

3

4

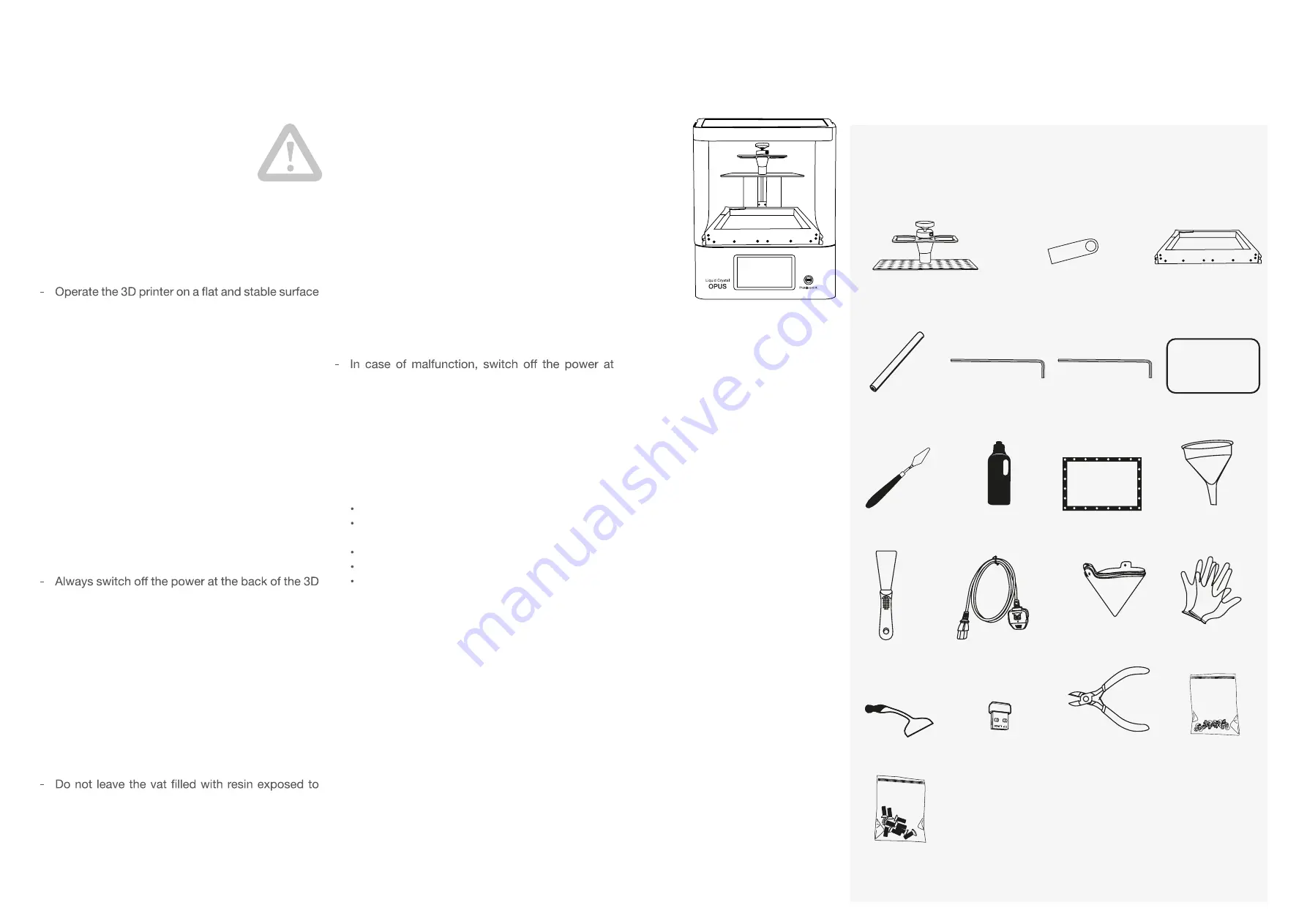

T25 L Shape Torx Key T10 L Shape Torx Key

Funnel

Power Cable

Soft Spatula

5x Paper

Resin Filters

1x Pair of Gloves

2x Vat Gaskets

2x spare Vat Film

Vat Cleaning Tool

Wi-FI Dongle

Cutter

1kg Sample Resin

Scraper

32 GB USB Flash Drive

Print Platform

(Factory Calibrated)

LC Opus Resin Vat

Liquid Crystal Opus

4. BOX CONTENTS

Silicone Mat

OPUS

Liquid Crystal

OPUS

Liquid Crystal

20x M3x4

Torx Screws

20x M5x10

Torx Screws