OPUS

Liquid Crystal

OPUS

Liquid Crystal

NOTE:

times. It should not be under tension but there

on all sides of the rings.

NOTE:

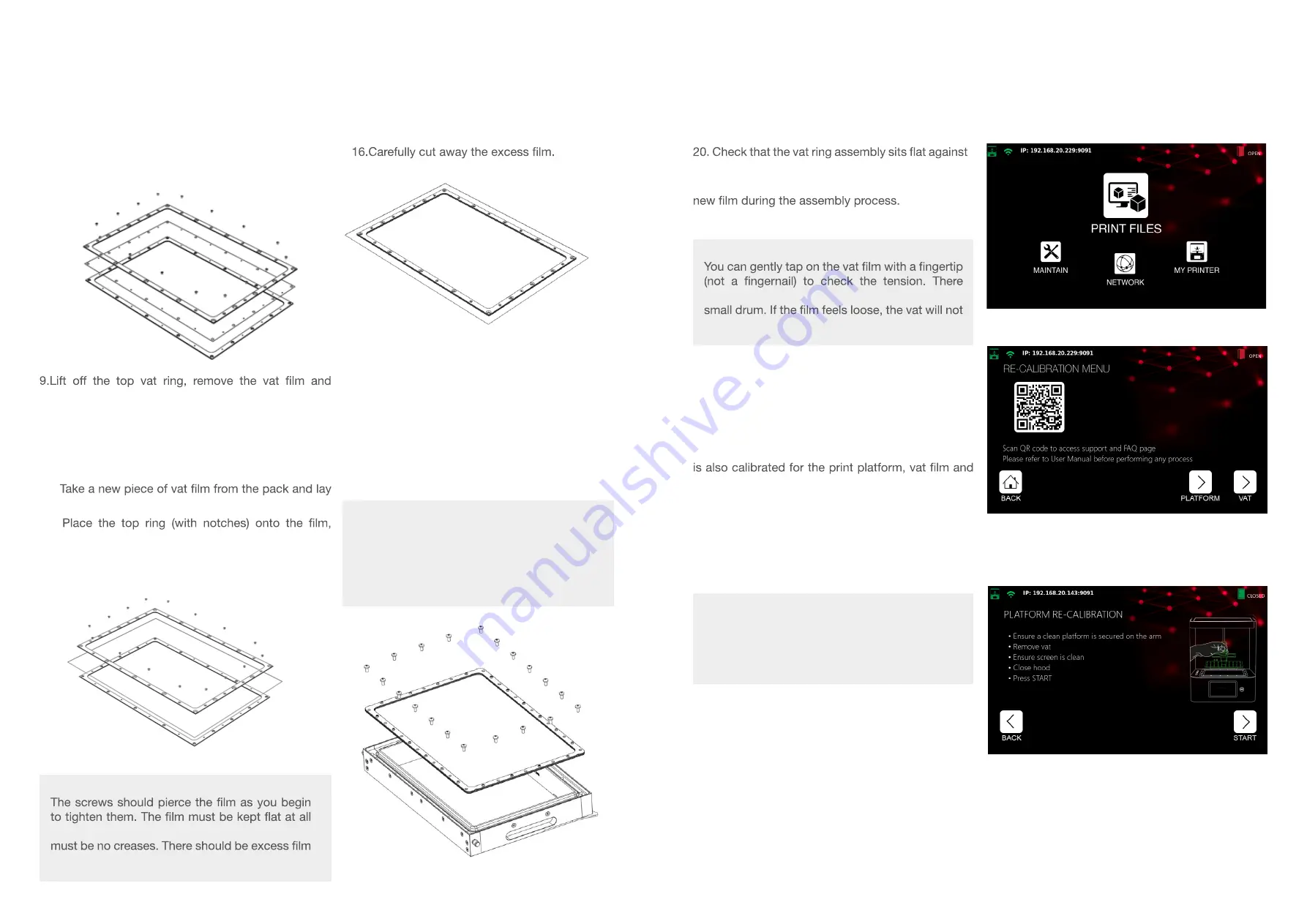

Tighten the screws in two phases. Fit all screws

loosely before fully tightening any. In both

phases, start with the corners, then the middle

of each edge. Finish the remaining screws in

opposite pairs.

NOTE:

When purchasing secondary print platforms and

resin vats, they do NOT need to be re-calibrated.

Both can be used interchangeably from printer

to printer.

NOTE:

should be a high-pitched, resonant sound like a

function properly.

8. Remove the small torx screws using the T10 L

Shape Torx Key, keep them to one side.

dispose of it.

10. Clean both vat rings thoroughly using paper towel

and cleaning solvent.

11. Ensure the silicone mat is clean.

12. Lay the bottom ring (without notches) down.

13.

it centrally over the ring.

14.

aligning the holes with those on the bottom ring.

15. Secure the two rings together using the smaller

torx screws with T10 L Shape Torx Key.

Print Platform Re-Calibration

To watch a video on Print Platform Re-Calibration

click here.

1. Remove the resin vat from the printer.

2. Ensure the print platform and screen are completely

clean, failure to do so could lead to damage of the

screen or inaccurate homing leading to print failures.

3.Secure the print platform into the printer by

tightening the turn knob.

4. On the ‘Main’ screen, select ‘Maintain’.

10.3 PRINT PLATFORM AND RESIN

VAT RE-CALIBRATION

The print platform has been pre-calibrated on our

production line according to strict QC procedures.

This ensures that the bottom surface of the print

platform is parallel with the LCD screen. The resin vat

LCD are all in contact once the platform reaches the

end of its movement to the bottom. The platform and

vat should not become misaligned during your time

using LC Opus. In the rare event that misalignment

occurs, you will need to reset the printer platform

and vat to their correct positions.

You will need: T25 L-Shape Torx Key

17.Place the vat ring assembly onto the vat with

the notched frame facing upwards.

18. Carefully pierce holes for the larger torx screws

using the tip of the torx key.

19. Secure the vat ring assembly to the vat body

using the larger torx screws with the T25 L Shape

Torx Key.

the vat body with no visible gaps.

21. Check that no damage has been caused to the

22. The vat is ready to use.

5. Select ‘Re-Calibrate’.

6. Select ‘Platform’.

7. Close the printer hood and select ‘Start’.

18

17