OPUS

Liquid Crystal

OPUS

Liquid Crystal

6 PRINTING

1. T

the USB port on the front of the machine.

1. Ensure that your LC Opus is positioned on a

stable, level surface where it will not be subject

to movement or vibrations during the printing

process.

2. Ensure that the print platform is completely clean

and dry, failure to do so may result in damage to

3. Load the print platform onto the print arm and

tighten fully by turning the main knob in a clockwise

direction.

9. Close the printer hood, the icon in the top right of

the touchscreen should show a green closed door.

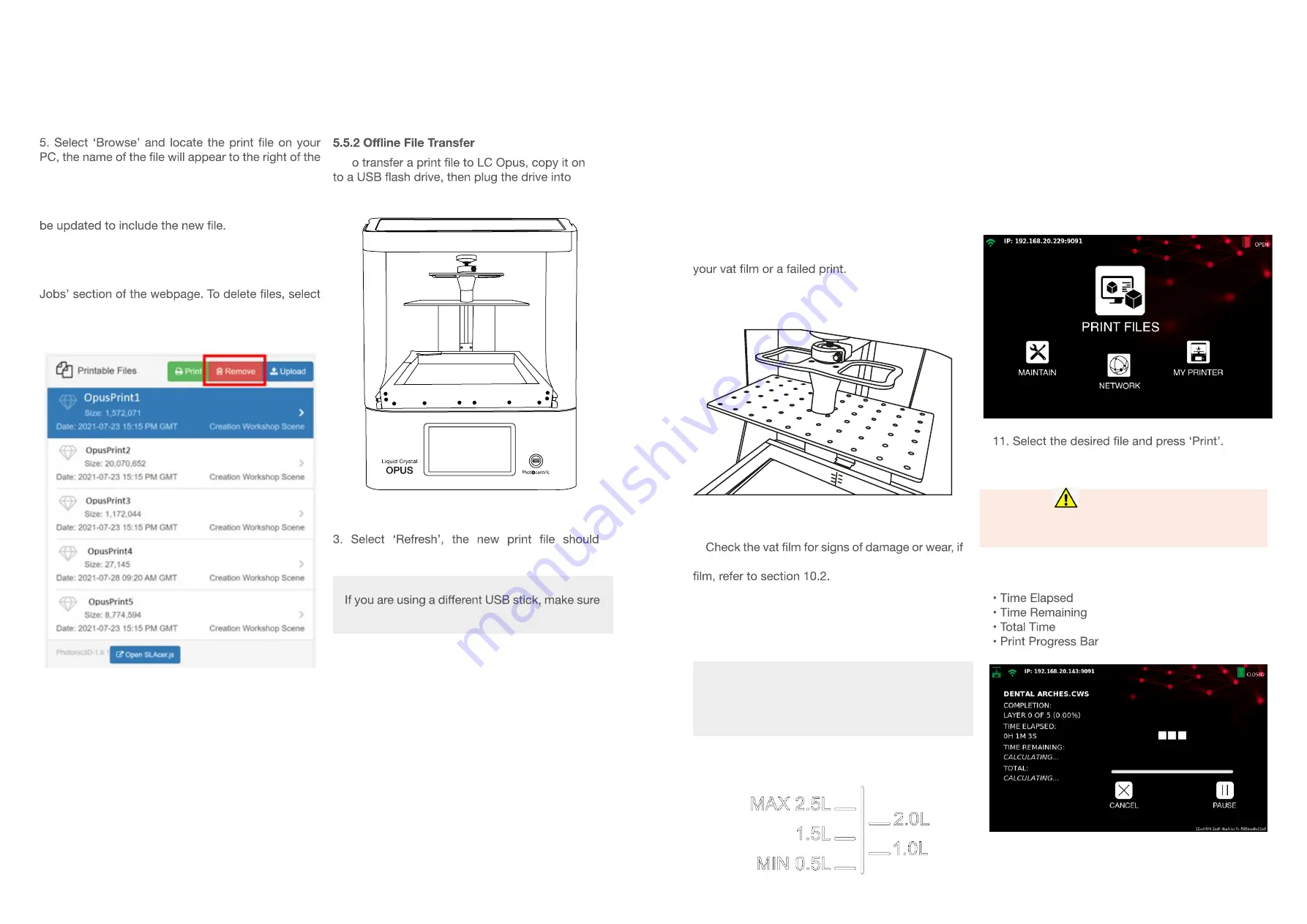

10. On the ‘Main’ screen, select ‘Print Files’.

8. Add required volume reported on Photocentric

Studio in addition to the 500 ml minimum level.

12. Your LC Opus will start the printing process.

13. During the print, the GUI will display various

information including:

4. Ensure that the resin vat is completely clean and

dry to avoid print failures or damage.

5.

you have any doubt about the condition of the vat

6. Slide the resin vat into the printer, you should

feel a positive click.

7. Pick the selected resin bottle, heat to 30°C and

shake well before use.

2. Select ‘Print Files’ from the ‘Main’ page.

appear.

NOTE:

its memory capacity does not exceed 32 GB.

NOTE:

Make sure you have added the same resin as

selected in Photocentric Studio. If correct resin

is not used, the print will fail.

WARNING

Do not open the printer hood during the printing

process.

‘Browse...’ button.

6. Select ‘Upload File’ and a progress bar will appear.

7. Once complete, the ‘Print Files’ list will

8. On LC Opus, go to ‘Main’ screen

and select ‘Print Files’.

The progress of prints can be monitored in the ‘Print

them then click ‘Remove’ at the top of the webpage.

10

9