1

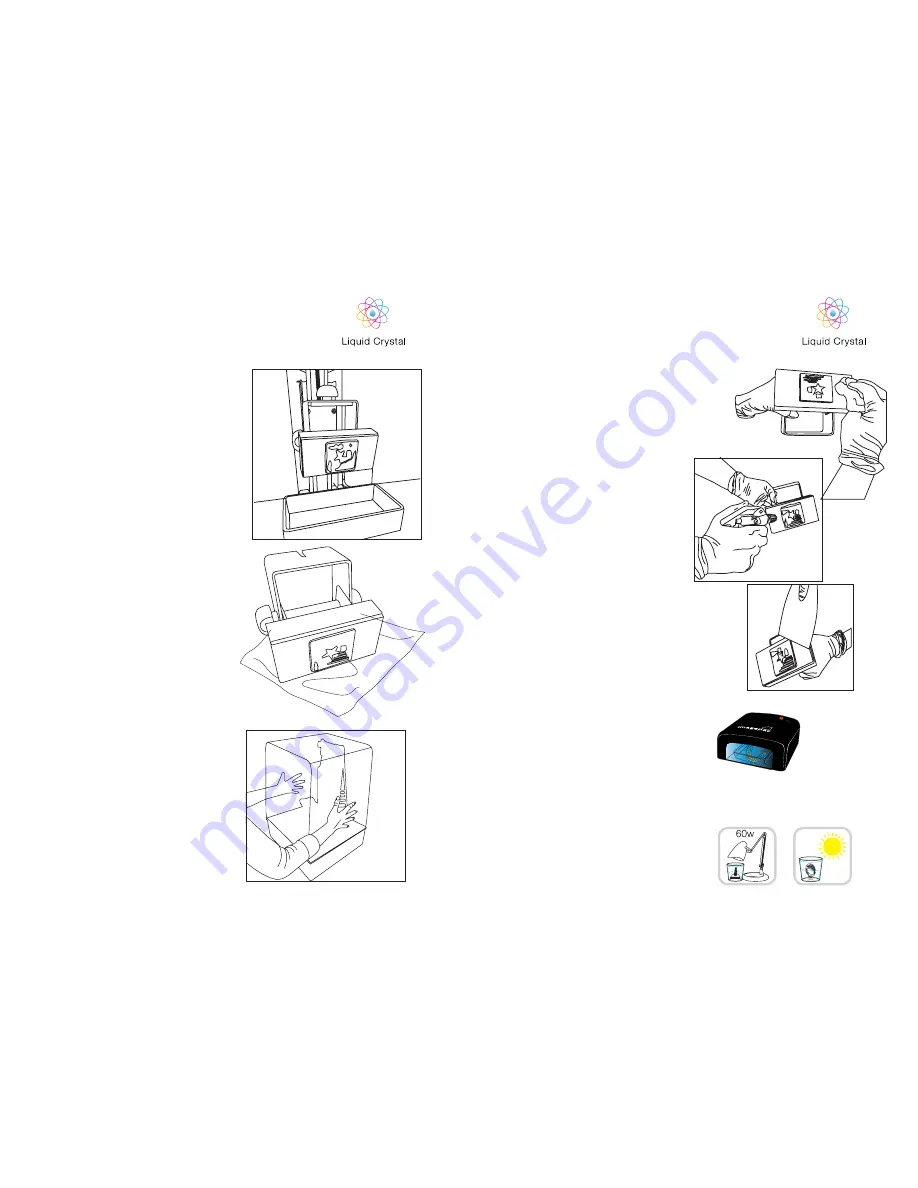

. When your print has finished, press the ‘+50’

button and the platform will rise to above the

level of the vat. Remove the hood and loosen

the two side bolts, tilt the platform slightly to

allow the resin to drip off. Adjust vat postion on

the tilted platform if needed. Put the hood back

on and leave to drain for a few minutes.

2

. Remove the hood again and with absorbent

paper under it, remove the platform completely

and set it down on the paper. Place the hood

back on to protect the resin in the vat from

light.

4. WASHING

13

14

3

. After all the liquid resin has drained off, gently

remove any excess polymer with absorbent

paper. The fastest way to clean it and achieve

a dry surface is by spraying or immersing it in

IPA. Spray thoroughly to make sure all of the

details, such as miniature holes, are free from

excess resin. Alternatively, you can wash it in

hot water and detergent. Likewise, you can use

a hot soapy water spray to make sure excess

resin has been cleaned from detailed areas.

To avoid a fragile part being damaged, you

can hold the part under running hot water and

gently clean it with a soft brush or sponge and

liquid detergent. To remove the object from the

platform, slide a scraper in at the base and cut

off the supports. Take care not to damage the

print as it will not achieve its full hardness until

after post exposing in light. A small ultrasonic

cleaner filled with fresh soapy water or IPA is

recommended to clean delicate objects.

1.

When completely clean, place it underwater in

light (UV, sunlight or a table light) for a least 30

minutes to remove the surface tack. The part

will only have around 1/4 of its final strength

before post-exposure and strength increases

slowly with more light. Full strength is achieved

with 30 mins in a UV unit, or 60 mins under a

normal 60W table lamp. Then remove from

water and dry.

5. HARDENING

30 mins

post exposure

60 mins

post exposure

60 mins

post exposure

PRECISION

PRECISION