6. Do NOT remove the screen film which is protecting

the upper surface of the screen and printer.

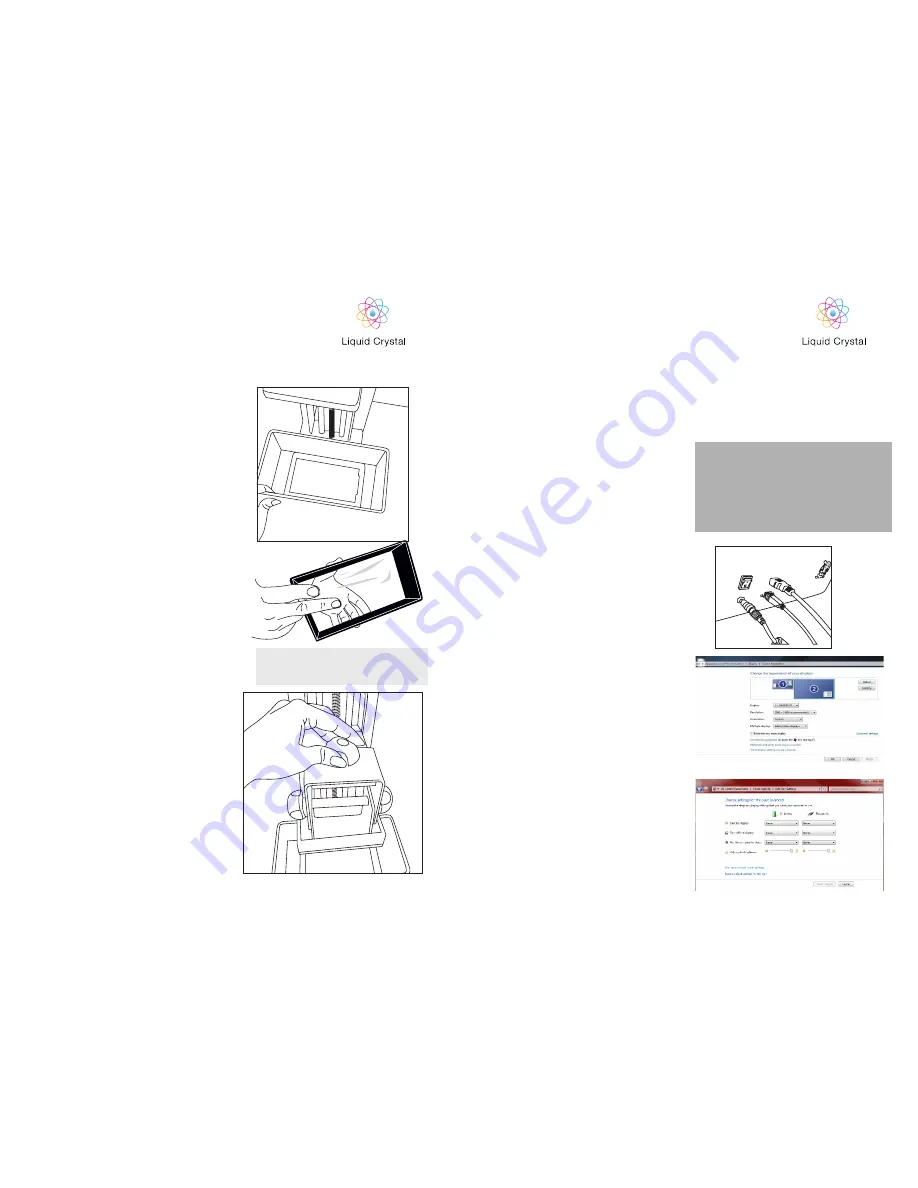

7. Remove one of the vats from the ancillary box

and place it centrally over the screen.

8. Check the film for any imperfections or holes;

any problems with the film may cause a leak.

The provided vats are disposable. You can use

them as long as the film is not pierced or the vat

is not damaged. However if you wish to you can

change the film. To change the film, see section

Re-Skinning Vat on pages 16-17. To check the

integrity of the vat, fill it with water and stand

for 5 minutes on absorbent paper, look for leaks

and dry thoroughly before use. Once inspected,

install the vat back into the machine. Before each

print, wearing gloves, sweep the film completely

down onto the screen to ensure that there are no

objects on or under the film.

9. Remove the platform from the ancillary box. Slide

it onto the printer arm and tighten the top knob

only, leave the two side knobs loose.

10. If you are experiencing difficulties setting up

your printer please visit our website:

www.photocentricgroup.com/support

The vat should be tensioned, this can be checked by

gently tapping on the film with your finger. not your

fingernail!

1.

Go to www.photocentricgroup.com and

download the “Liquid Crystal Precision Driver”

and “Creation Workshop for Liquid Crystal

Precision” which can be found on the support

page. The latest version is always online.

2.

Install the driver “CypressDriverinstaller_1”

on your computer so that the USB port will

recognize the Liquid Crystal Printer. Restart your

computer.

3. Make sure the HDMI, USB and Power cables

are plugged into the printer and then turn on the

power using the rocker switch at the back.

4. Go to your computer desktop, right click and

open “Screen resolution”. Set your screens to

“Multiple Displays” and “Extend this display

mode”, keeping your computer monitor as the

main screen. Make sure that the printer’s screen

is set to a resolution of 2560 x 1440. There are

videos online if you need further help.

5. Configure your computer so that the screen-

saver does not come on and ensure that it does

not have the power-saving mode enabled. If you

forget to do this your computer may shut down

mid process and the printer will switch off.

1.1. SOFTWARE

INSTALATION

MINIMUM COMPUTER

REQUIREMENTS

• Dual Core processor or above

• Windows

• Software NOT compatible with MAC and

Linux

• 2 GB RAM memory or above

CREATION WORKSHOP

7

8

PRECISION

PRECISION