6. Execute the Creation Workshop software by

double clicking on “CreationWorkshop.exe”. If

the software requires a license number insert the

license number supplied.

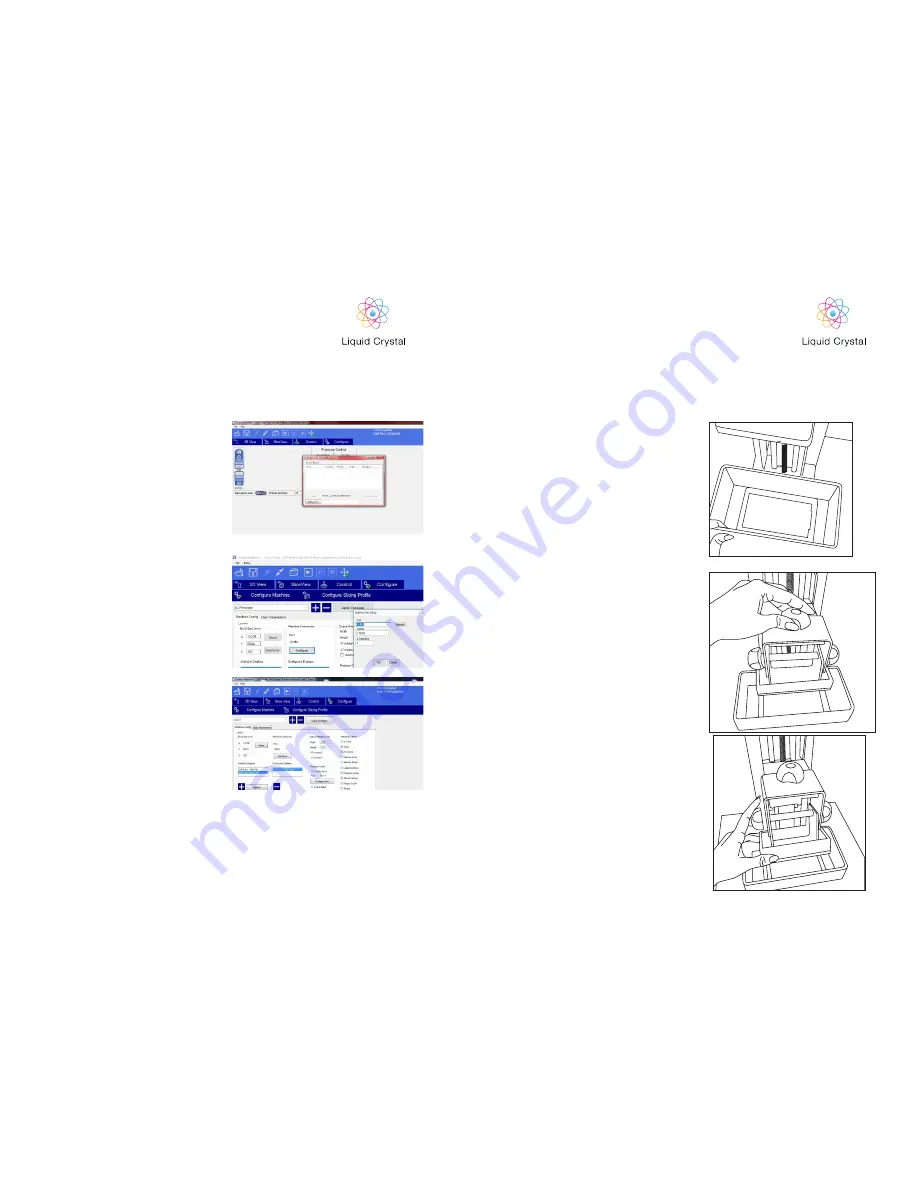

7. In Creation Workshop, click on “Configure”, and

then open the subfolder “Configure Machine”. In

the configuration folder connect the printer to the

computer by clicking on the button “Configure”

in the Machine Connection section. Select the

port you have connected the USB to and set the

speed to 115200 and data bits to 8. Press “OK”

on available displays and then select refresh.

Once refreshed, choose Display 2560x1440 and

press + to add it to Configured Screen and then

press, Apply Changes. Now click [CONNECT

ICON] to connect your computer and the Liquid

Crystal.

8. If you are experiencing difficulties to start or

connect your printer, go to our website www.

photocentricgroup.com, and visit “Support”.

You will find videos that will run you through the

issues you may find due to specific computer

settings. Should you still find difficulties, please

contact your national supplier or contact us at

[email protected].

9

10

Ensure that the screen is clean (wipe with a little

liquid soap and warm water if it’s dirty) and dry.

Place the vat centrally over the screen.

Ensure the base of the vat film is clean. Wearing

gloves wipe the bottom of the vat film with a

piece of abosorbent paper. You can use soapy

water or IPA to help cleaning. Make sure the

print platform is clean by scrubbing with liquid

soap and water and wipe dry. Place the platform

on the print arm.

Tighten the upper bolt and loosen the two side

bolts on the print platform.

In Creation Workshop, go to the control tab and

press the home button (located at the top of the

z-Axis controls).This will lower the platform until

the home switch is activated. Align the platform

so that it is directly over the screen and tighten

the central bolt.

Wearing gloves, press down hard in the middle

of the metal platform and then tighten the two

side bolts. Press ‘+10’, and the platform will lift

10mm, pour the amount of resin you need, then

press ‘-10’ to return it to screen height and you

are homed!

2. THE HOMING

PROCEDURE

PRECISION

PRECISION