3. Installation/Handling

Acoustic pressure level

could reach 50 - 86 dB(A) at 1 m

distance depending on air fluid cooler size and rotation speed

under normal operating conditions. An inappropriate location or

operation under extreme conditions could cause an increase in

acoustic pressure level and a decrease in cooling capacity.

Identification plate

The identification plate of the air fluid cooler is fitted on the fan

housing and contains the following information: See Figure 2.

A

– Part number.

B

– Designation.

C

– Serial number.

D

– Date of delivery

(year and week, e.g. 1018, i.e. year 2010 and week 18).

Replace a damaged or missing identification plate as soon as pos-

sible.

Fluids

WATER: add corrosion inhibitors to the water to avoid corrosion.

All materials included in the cooling circuit must be considered for

choice of correct inhibitor.

GLYCOL: Mix glycol and water in a ratio of 50% / 50% before filling!

Never mix different types and different brands of glycol. We recom-

mend the use of demineralized or osmosis water.

Additives like Glysantin G48 or TYFOCOR have demonstrated their

ability to prevent corrosion in a closed cooling circuit.

See supplier information regarding water quality, additive quantity

and periodic replacements.

CAUTION: Follow material safety data sheets (MSDS) of glycol

manufacturers! Please note that the coolant is considered hazard-

ous waste and needs to be disposed accordingly.

Filtration

The use of a filter allows reducing the presence of impurities or

chips in the liquid circuit in order to prevent any obstruction.

Check the contamination with particles and biological changes,

the composition of the water-glycol mixture and the current pos-

sible temperature range in which it can be operated at regular

intervals. Change the filter elements if the values deviate from the

values at initial start-up. Follow the filter manufacturer’s instruc-

tions and the fluid manufacturer’s MSDS.

Suggestion : use spin-on filter design in a bypass channel.

Installation

Lifting

Caution

Risk of bodily injury. To prevent physical harm when

lifting the unit, use the correct lifting technique. Make sure

that all lifting devices are free from damage and approved

for the weight of the air fluid cooler.

Mounting

The QDC air fluid cooler can be mounted in any position. Howev-

er, an upright installation standing on its feet is recommended. A

free space corresponding to a minimum of half the height of the

matrix should be available in front of and behind the air fluid cool-

er to allow for optimal cooling capacity and low acoustic power

level. See Figure 3.

An inappropriate location or operation under extreme conditions

could cause an increase in acoustic pressure level and a decrease

in cooling capacity.

Important

The cooler matrix is designed for maximum dynamic

working pressure 14 bar. When the cooler is installed in a return

line, there should be no pressure spikes. If this is not possible, an

offline cooling system should be used.

Electrical connection

Precaution

Prior to connecting the DC motor to the supply

system, make sure the information on the motor label

corresponds to specified direct current.

The DC motor must only be installed according to general and

electrical safety rules. Circuit diagram, see Figure 6 and Interface

Hardware for digital control, see p.12 (5.07)

Precaution

Be careful when connecting. Improperly

made connections, damaged cables, etc. could cause

components to become live or result in the incorrect di-

rection of rotation of the DC motor and fan.

Note!

A motor overload protection is recommended. The size

of the overload protection/fuse, depends on fan size and air flow

across the cooler. Contact Parker concerning motor protection/fuse

size. An automotive fuse according ISO8820 must be chosen

and used by the customer in the application wire harness.

Each drive must be protected by the unique proper fuse (e.g. in

case of double fan modules, two fuses are needed).

The QDC air fluid cooler can be fitted with a thermo sensor on the

inlet and outlet side for temperature control. The fan RPM can be

controlled by the integrated inverter, see p.12 (5.07)

Handling

Prior to initial start-up

Precaution

Check that the air fluid cooler is securely fixed

and correctly connected.

We recommend that you proceed as follows prior to start-up:

1. Run the air fluid cooler with the system fluid.

2. Filter the fluid before passing through the cooler.

See Technical specification for recommended fluid compatibility.

Prior to start up

Precaution

Do not start the air fluid cooler if there is a risk

of damage to person, property or environment.

Check that:

• all air fluid cooler parts are free from damage

• the air fluid cooler is correctly connected

• the fan rotates freely (use hand force)

• all liquid connections are tight

• the inside of the fan housing is free from objects that could be

thrown around and cause bodily injury or damage to property.

At start-up

Check that:

• the direction of rotation of the fan and the air flow corresponds

to indications on the fan housing

• the air fluid cooler is free from abnormal noise and vibrations.

• the air fluid cooler is free from leaks

In order to protect the cooler matrix, use a by-pass valve when

operating in cold start mode/with thick lubricating oils.

During operation

Caution

Risk of severe burns. The air fluid cooler could

become extremely hot during operation. Make sure that the

air fluid cooler is cool before touching.

Maximum permitted fluid temperature in the cooler matrix is

120 °C.

The cooler matrix is designed for maximum allowed dynamic

working pressure of 14 bar.

Do not overload the DC motor (see p.12 (5.07)). See identification

plate.

Note!

Use hearing protection when standing in the immediate vi-

cinity of an operating air fluid cooler for long periods of time.

Preventive maintenance

Preventive maintenance work must be carried out at regular

intervals. Make sure that:

• there is no abnormal noise or vibrations

• air fluid cooler is securely fixed

• the cooler matrix is clean - debris will reduce the cooling

capacity

• the air fluid cooler is free from damage, replace damaged

components

• the air fluid cooler is free from leaks, take appropriate

measures

• warning labels are in good condition, replace any damaged/

missing label immediately.

Annually:

Check the electrical installation.

Cleaning

Precaution

Risk of bodily injury. Prior to cleaning,

disconnect all motor power supplies.

Caution

Risk of severe burns. The air fluid cooler could be-

come extremely hot during operation. Make sure the air fluid

cooler is cool before touching.

Air fluid cooler

When cleaning the exterior of the cooler, for

instance using water, disconnect all power supplies. Be aware

of the DC motor protection standard.

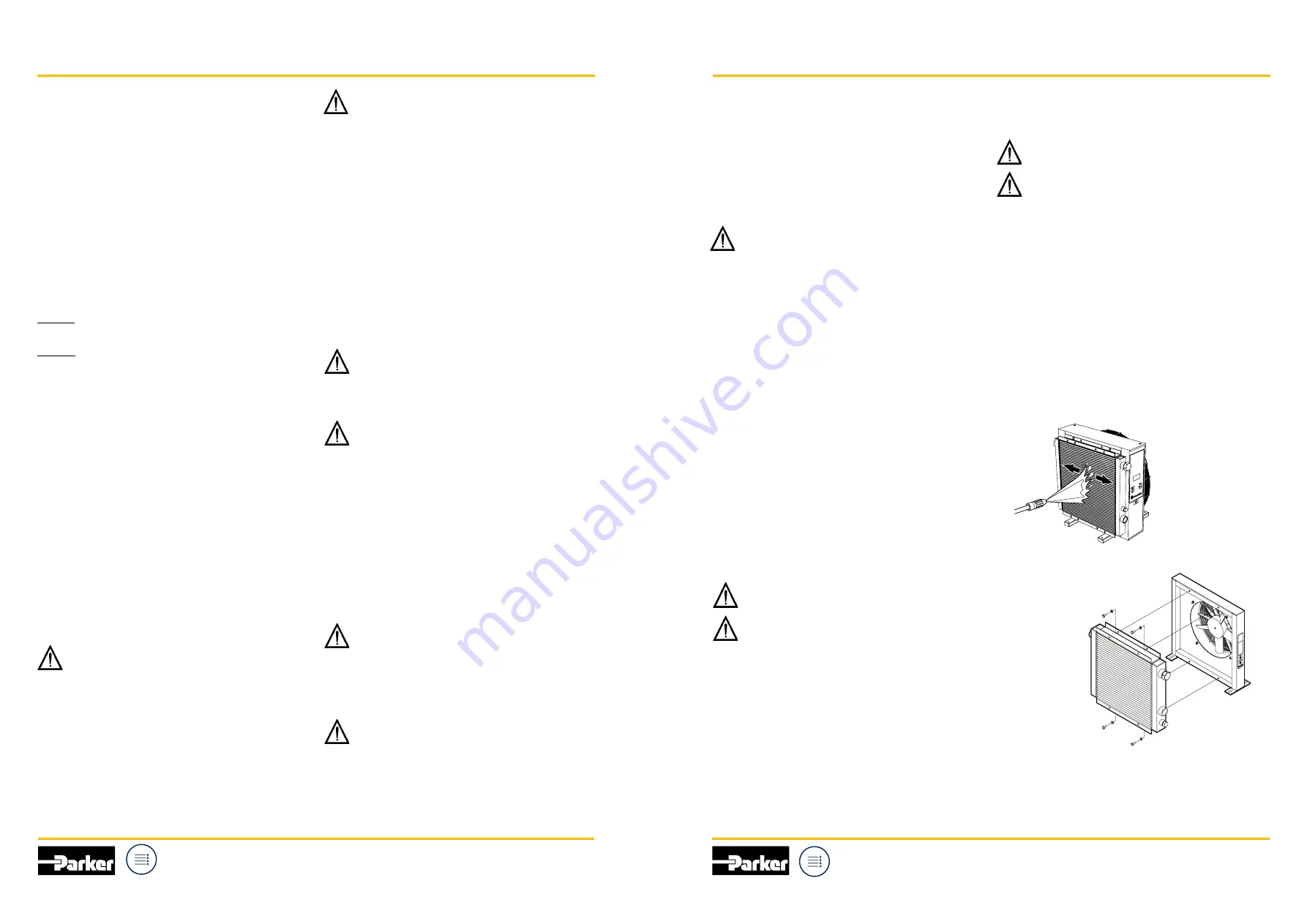

Cooler matrix

The air fins of the matrix can be cleaned by blow-

ing through with compressed air

1

. If necessary a high-pressure

water system can be used

3

. When using a high-pressure water

system point the jet parallel to the air fins. See Figure 7.

Fan housing

Remove the cooler matrix when cleaning the in-

side of the fan housing. To clean the inside of the fan housing,

use compressed air

1

. If necessary suitable cleaning

agents

2

can

be used. Blow with compressed air

1

from the electric motor side

through the fan guard.

Maintenance

Parker shall not be held responsible for any consequences due to

repair and/or modification made by the customer.

Caution

Risk of severe burns. The air fluid cooler could

become extremely hot during operation. Make sure the air

fluid cooler is cool before touching.

Caution

Risk of bodily injury. Disconnect the motor power

supply prior to maintenance.

Dismounting the cooler matrix

1. Turn off the system.

2. Disconnect the electric motor power and control supply.

3. Make sure that the system is depressurized.

4. Disconnect the liquid inlets and outlets.

5. Disconnect the flexible hoses from the cooler matrix.

6. Unscrew the screws with washers fixing the cooler matrix to

the fan housing: See Figure 8.

7. Remove the cooler matrix.

Mounting of the cooler matrix

1. Locate the cooler matrix.

2. Fit the cooler matrix to the fan housing. See Figure 8.

3.

Connect the flexible hoses to the cooler matrix.

4. Connect the electric motor power and control supply.

5. Proceed to Paragraph Handling:

Prior to start-up and At start-up.

D

AIR OIL

COOLER

LDC

LDC

7

AIR

OIL

COO

LER

LAC

LAC

8

Precaution

Risk of bodily harm. Make sure that the air fluid

cooler is securely fixed.

Connection of the cooler matrix

Connect the cooler matrix using flexible hydraulic hoses. Make

sure that all connections and hoses are sized according to the

system pressure, flow, temperature and type of liquid.

Connect the hoses to the cooler matrix as illustrated below. See

A

– Inlet |

B

– Outlet |

C

– Inlet G 1/2 sensor port

D

– Outlet G 1/2 sensor port

Dimensions on connections are cooler matrix size dependent,

see catalogue.

Connection chart, See Figure 5.

1

Follow resp. country safety guidelines when using compressed air.

2

Use 99% isopropyl alcohol on surface and follow MSDS.

3

If needed, use cleaning agents. Make sure they are suitable for dissolving

the contamination without damaging the materials or coatings, follow

MSDS.

6

7

Parker Hannifin

Cylinder and Accumulator

Division Europe

Manual and Installation Guide

Manual and Installation Guide

QDC

for electrified mobile applications

QDC

for electrified mobile applications

Parker Hannifin

Cylinder and Accumulator

Division Europe