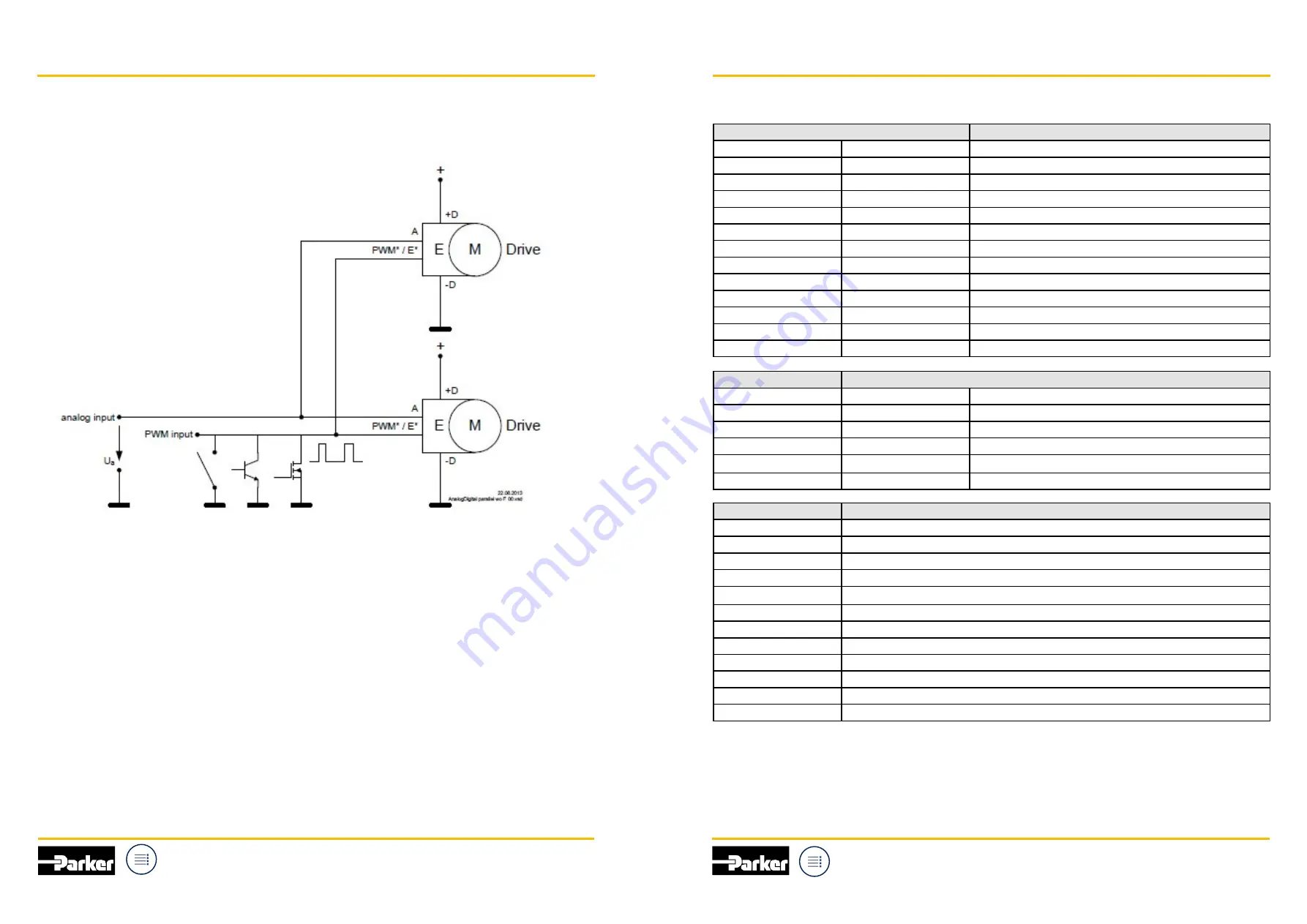

5.16 Interface Parallel Configuration

The Drives can be used in a parallel configuration in the PWM driven modes as well as in analog driven

modes and also in the combines analog / PWM mode in such a way that the control lines are connected in

parallel as shown in below for the example of two Drives.

There is no limitation from the Drive‘s point of view in paralleling them. Nevertheless from the CCU’s point of

view it has to be considered that all of the Drives needs a certain current each on the signal lines PWM* / E*

and A. This has to be taken into account for dimensioning the driver stage which controls digitally via the

PWM* / E* inputs of the Drives or which controls analog via the A inputs of the Drives. The output driver

stage of the CCU needs to be capable of driving minimum the input currents of PWM* / E* and / or A times

the number of the Drives.

5.17 Units and Acronyms

Unit

Physical Quantity

%

percent

Proportionality

Ω

Ohm

Electrical Resistance

°C

degree Celsius

Temperature

A

Ampere

Current

h

hours

Time

dBA

deciBel (A-weighting)

Sound Pressure Level

Hz

Hertz

Frequency

min

minute

Time

Pa

Pascal

Pressure

RPM

Revolutions per minute

Rotation Frequency

s

second

Time

V

Volt

Voltage

W

Watt

Power

Prefix

Dimension

M

10

6

mega

k

10

3

kilo

m

10

-3

milli

ų

10

-6

micro

n

10

-9

nano

p

10

-12

pico

Key Word

Description

AMPL_IN

Amplitude PWM Input Signal

CCU

Custom Control Unit

Drive

Motor with axially Integrated Electronics

IGN

Ignition (KL15)

PWM

Pulse Width Modulation

R

i

Input Resistance

SBL

Sealed Brushless

T

Temperature

T

AMB

Ambient Temperature

U

B

Supply Voltage

U

N

Nominal Supply Voltage

rms

Root Mean Square

20

21

Parker Hannifin

Cylinder and Accumulator

Division Europe

Parker Hannifin

Cylinder and Accumulator

Division Europe

Manual and Installation Guide

Manual and Installation Guide

QDC

for electrified mobile applications

QDC

for electrified mobile applications