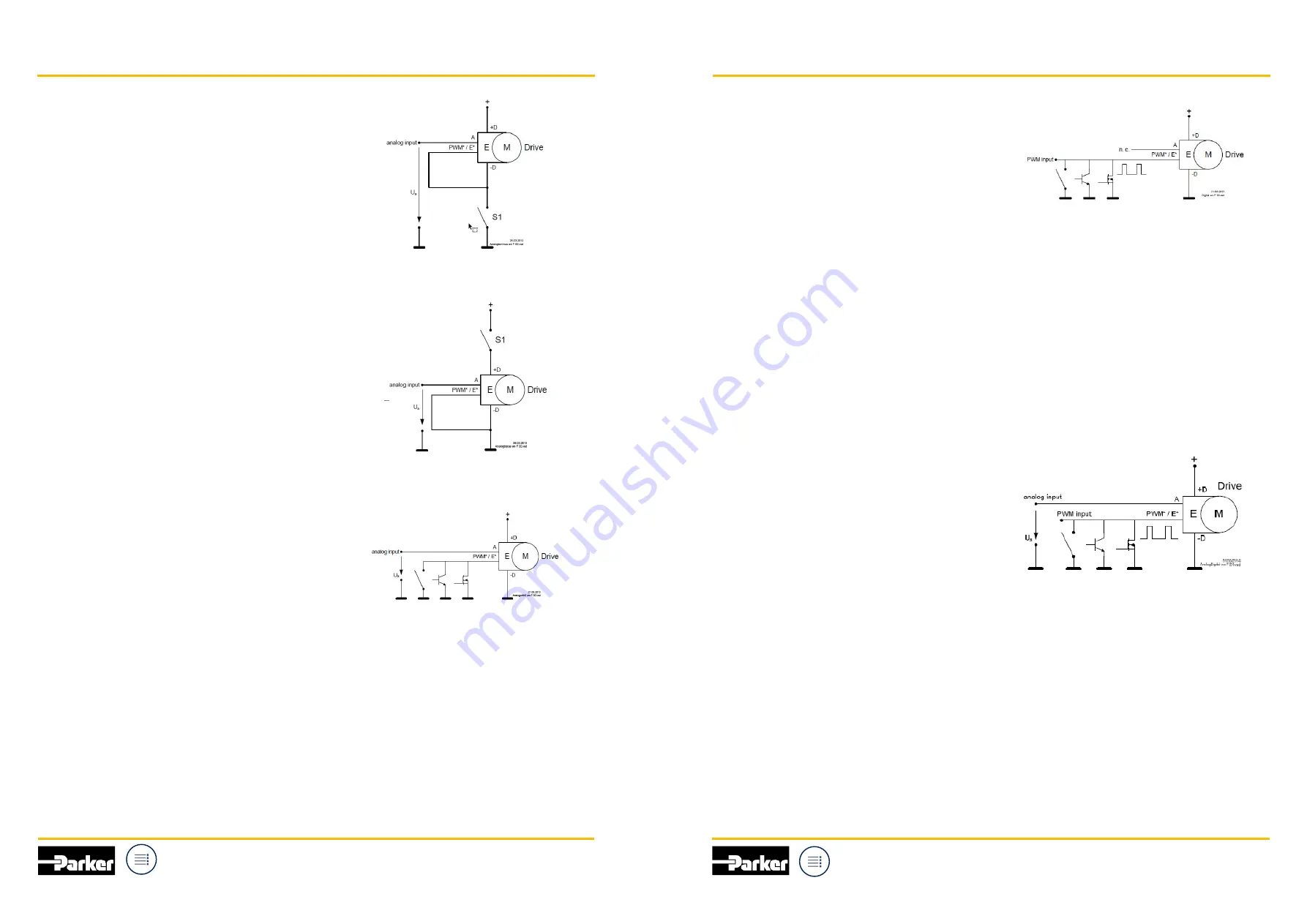

5.15.4 Interface Mode 04: Analog Control 1

5.15.5 Interface Mode 05: Analog Control 2

When the switch S1 is switched on the Drive goes after

the initialization of the electronics to the speed

requested by the analog input A.

The appropriate current rating for this “switch” has to

be dimensioned according to the current consumption

of the Drive.

When the switch S1 is switched on the Drive goes after

the initialization of the electronics to the speed

requested by the analog input A.

The appropriate current rating for this “switch” has to

be dimensioned according to the current consumption

of the Drive.

In mode 6 the Drive can stay always on supply voltage

and is controlled by a low current enable input which

can be driven by simple low cost low side signal driver

in the CCU.

When the enable input PWM* / E* goes to high, the

Drive goes after a short time into the quiescent current

mode.

When the enable pin PWM* / E* is driven low, the

Drive goes to the speed requested by the analog input

A after the initialization of the electronics.

The appropriate sink current rating of the driver for the

enable pin PWM* / E* has to be dimensioned

according to the current consumption of the pin

PWM* / E*.

The circuit structure to drive the pin PWM* / E* can be

any active low “open collector”.

In this operating mode the supply voltage plus is

usually connected permanently. To run the Drive first

the pin PWM* / E* has to be connected to supply

voltage minus and afterwards the Drive speed can be

then controlled with an analog voltage on the pin A.

5.15.6 Interface Mode 06: Analog Control with Enable Low

5.15.7 Interface Mode 07: Digital Control

5.15.8 Interface Mode 08: Mixed Analog / Digital Control

In mode 7 the Drive can stay always on supply voltage

and is controlled by a low current PWM and enable

PWM* / E* input which can be driven by simple low

cost low side signal driver in the CCU.

When the enable input PWM* / E* goes to high, the

Drive goes after a short time into the quiescent current

mode.

When the enable pin PWM* / E* is driven with PWM,

the Drive goes to the speed requested by the duty

cycle after the initialization of the electronics.

The appropriate sink current rating of the driver for the

enable pin PWM* / E* has to be dimensioned

according to the current consumption of the pin

PWM* / E*.

The circuit structure to drive the pin PWM* / E* can be

any active low “open collector”.

In this operating mode the supply voltage plus is

usually connected permanently. To run the Drive on

the pin PWM* / E* a PWM signal has to be applied and

with the duty cycle of the PWM signal the Drive speed

can be then controlled.

In mode 8 the Drive can stay always on supply voltage

and is controlled by a low current PWM and enable

PWM* / E* input which can be driven by simple low

cost low side signal driver in the CCU.

When the enable input PWM* / E* goes to high, the

Drive goes after a short time into the quiescent current

mode.

When the enable pin PWM* / E* is driven low (switched

to supply voltage minus), the Drive goes to the speed

requested by the analog input A after the initialization of

the electronics (if the electronics is not already activated).

When the enable pin PWM* / E* is driven with PWM,

the Drive goes to the speed requested by the duty

cycle after the initialization of the electronics (if the

electronics is not already activated).

The appropriate sink current rating of the driver for the

enable pin PWM* / E* has to be dimensioned according

to the current consumption of the pin PWM* / E*.

The circuit structure to drive the pin PWM* / E* can be

any active low “open collector”.

In this operating mode the supply voltage plus is

usually connected permanently. To run the Drive on

the pin PWM* / E* a PWM signal has to be applied and

with the duty cycle of the PWM signal the Drive speed

can be then controlled. If the pin PWM* / E* is switched

to supply voltage minus the Drive speed can be then

controlled with an analog voltage on the pin A.

So a mixed control with either digital or analog input is

possible. The priority has the digital PWM signal.

18

19

Parker Hannifin

Cylinder and Accumulator

Division Europe

Parker Hannifin

Cylinder and Accumulator

Division Europe

Manual and Installation Guide

Manual and Installation Guide

QDC

for electrified mobile applications

QDC

for electrified mobile applications